Contents

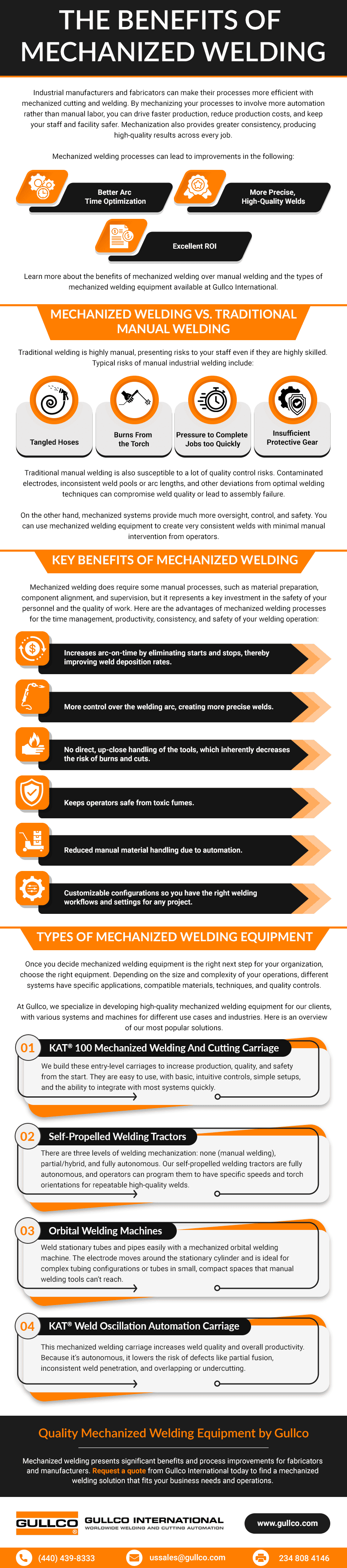

Quick Summary: Learn more about the benefits of mechanized welding over manual welding and the types of mechanized welding equipment available at Gullco International.

Industrial manufacturers and fabricators can make their processes more efficient with mechanized cutting and welding. By mechanizing your processes to involve more automation rather than manual labor, you can drive faster production, reduce production costs, and keep your staff and facility safer. Mechanization also provides greater consistency, producing high-quality results across every job. Mechanized welding processes can lead to improvements in the following:

- Better arc time optimization

- More precise, high-quality welds

- Excellent ROI

Mechanized Welding vs. Traditional Manual Welding

Traditional welding is highly manual, presenting risks to your staff even if they are highly skilled. Typical risks of manual industrial welding include:

- Tangled hoses

- Burns from the torch

- Pressure to complete jobs too quickly

- Insufficient protective gear

Traditional manual welding is also susceptible to a lot of quality control risks. Contaminated electrodes, inconsistent weld pools or arc lengths, and other deviations from optimal welding techniques can compromise weld quality or lead to assembly failure.

On the other hand, mechanized systems provide much more oversight, control, and safety. You can use mechanized welding equipment to create very consistent welds with minimal manual intervention from operators.

Key Benefits of Mechanized Welding

Mechanized welding does require some manual processes, such as material preparation, component alignment, and supervision, but it represents a key investment in the safety of your personnel and the quality of work. Here are the advantages of mechanized welding processes for the time management, productivity, consistency, and safety of your welding operation:

- Increases arc-on-time by eliminating starts and stops, thereby improving weld deposition rates

- More control over the welding arc, creating more precise welds

- No direct, up-close handling of the tools, which inherently decreases the risk of burns and cuts

- Keeps operators safe from toxic fumes

- Reduced manual material handling due to automation

- Customizable configurations so you have the right welding workflows and settings for any project

Types of Mechanized Welding Equipment

Once you decide mechanized welding equipment is the right next step for your organization, choose the right equipment. Depending on the size and complexity of your operations, different systems have specific applications, compatible materials, techniques, and quality controls.

At Gullco, we specialize in developing high-quality mechanized welding equipment for our clients, with various systems and machines for different use cases and industries. Here is an overview of our most popular solutions.

KAT® 100 Mechanized Welding And Cutting Carriage

We build these entry-level carriages to increase production, quality, and safety from the start. They are easy to use, with basic, intuitive controls, simple setups, and the ability to integrate with most systems quickly.

Self-Propelled Welding Tractors

There are three levels of welding mechanization: none (manual welding), partial/hybrid, and fully autonomous. Our self-propelled welding tractors are fully autonomous, and operators can program them to have specific speeds and torch orientations for repeatable high-quality welds.

Orbital Welding Machines

Weld stationary tubes and pipes easily with a mechanized orbital welding machine. The electrode moves around the stationary cylinder and is ideal for complex tubing configurations or tubes in small, compact spaces that manual welding tools can’t reach.

KAT® Weld Oscillation Automation Carriage

This mechanized welding carriage increases weld quality and overall productivity. Because it’s autonomous, it lowers the risk of defects like partial fusion, inconsistent weld penetration, and overlapping or undercutting.

Quality Mechanized Welding Equipment by Gullco

Mechanized welding presents significant benefits and process improvements for fabricators and manufacturers. Request a quote from Gullco International today to find a mechanized welding solution that fits your business needs and operations.

Relevant Resources

Frequently asked questions

Find quick answers to your questions here, ask our AI assistant, or contact us for any additional inquiries.

Gullco’s automation solutions can be tailored to fit most applications. Our products are designed for flexibility and customization. To determine the best approach for your needs, please provide some details about your project. We’re happy to discuss how we can help you achieve optimal results.

Thanks for your interest in Gullco products! For accurate pricing and to discuss your specific needs, we recommend you Request a Quote and your local distributor will promptly respond.

Gullco International has presence worldwide. To locate the distributor in your area, visit our distributor locator and choose your region and location.

Absolutely! We’d be happy to schedule a product demonstration for you. Please let us know which product(s) you’re interested in and your preferred date and time, and we’ll get that arranged. We look forward to showing you how Gullco can improve your operations.

You can locate your product manual in our Resource library.

That’s a great question! We’re really proud of the ruggedness of our Gullco products. A big part of it comes from our commitment to North American manufacturing. We’ve invested over $12 million in state-of-the-art CNC equipment to ensure precision and durability. Plus, we do most of the manufacturing in-house, which gives us tight control over quality.

Ready to get started?

With over seven decades of experience and a worldwide reach, we synthesize the skills, knowledge, and experience to offer reliable, innovative solutions to automate welding and associated processes. We are committed to continual improvement, developing new welding automation systems and equipment to address the ever-changing needs of the industry.