Welding & Cutting

Automation equipment that helps our customers reduce defect rates, improve productivity, and decrease overall costs.

- Welding & Cutting Automation Carriages

- Weld Oscillation Automation Carriages

- Weld Gouging Automation Carriages

Plate Beveling

We design and manufacture plate bevelers for our customers to create angled edges on metal plates, preparing them for welding.

- Portable Plate Bevelers

- Underside Plate Bevelers

- Heavy Duty Plate Bevelers

Ceramic Weld Backing

Ceramic weld backing products enable manufacturers to eliminate defects and rework in their welding operations.

- Eliminate unnecessary gouging & grinding

- Non-toxic

- Sizes 1/4″ (6.3 mm) to 2″ (50.8 mm)

Electrode Ovens

Electrode ovens ensure the maintenance of proper electrode and flux moisture levels during welding operations.

- Portable Electrode Ovens

- Compact, In-Shop Electrode Ovens

- Flux Hoppers

Featured Products

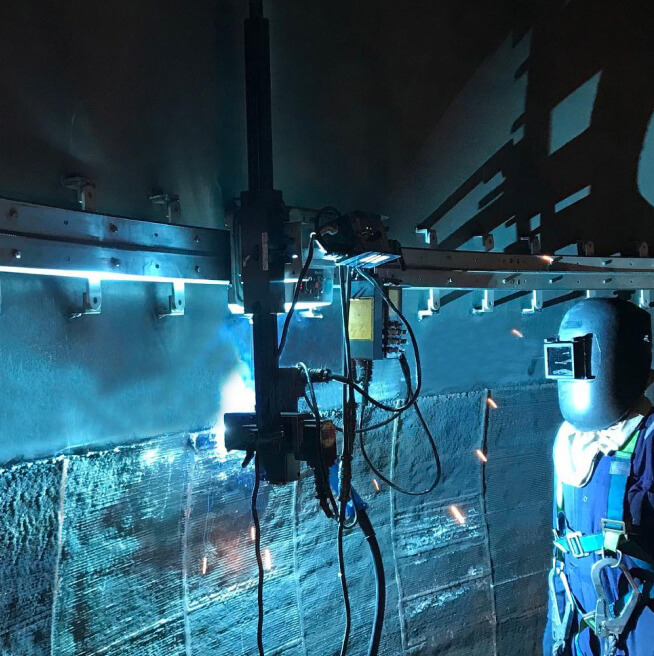

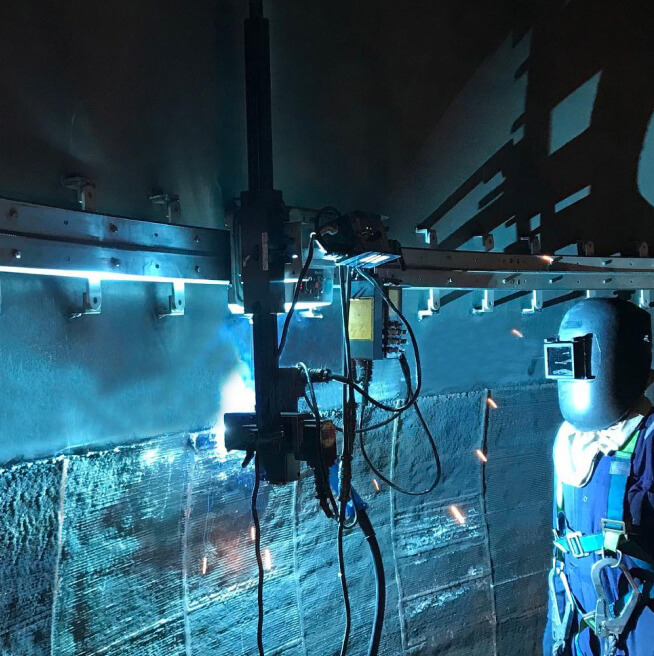

Shipbuilding Applications

The welding during shipbuilding is the most expensive and time consuming component of the process. It is important to reduce consumable waste, material handle and downtime and improve weld deposition rates.

- Improve worker safety

- Increase arc time through automation

- Reduce costs & minimize waste/rework

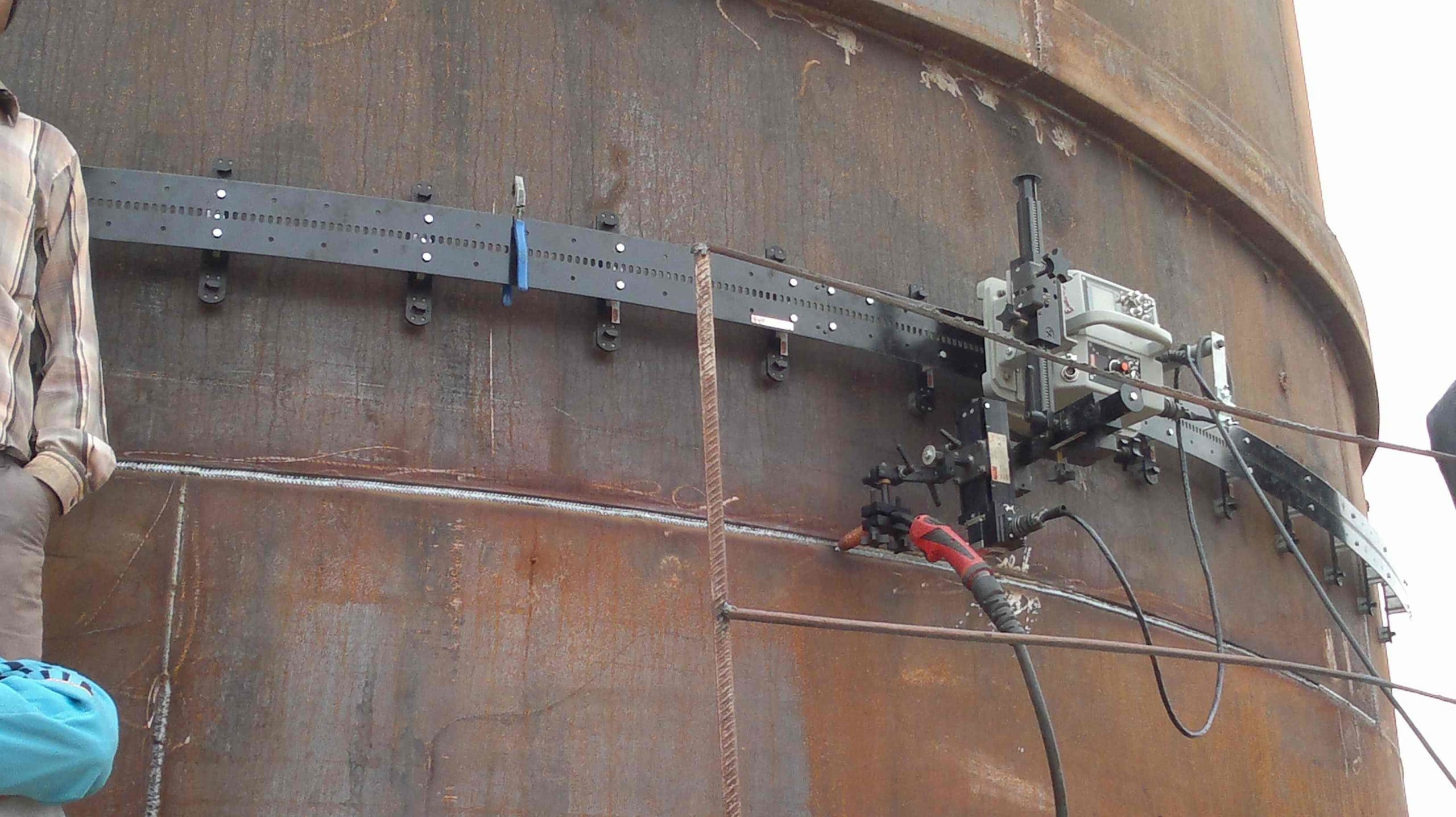

Tank Welding Applications

Manual welding tasks in metal storage tank fabrication require substantial time and effort, incurring higher labor costs and an increased risk of human error, which impacts project deadlines.

- Improve weld quality

- Improve worker productivity

- Improve accuracy while reducing consumable waste

Infrastructure Applications

Welding plays a critical role in infrastructure, aiding in the fabrication of structurally sound frameworks as well as repairing and restoring unstable or broken existing infrastructure.

- Increase competitiveness during bidding process

- Overcome skill labor shortages

- Meet aggressive project deadlines

Military Applications

Military processes have some of the most stringent requirements for precision and reliability when it comes to the fabrication and upkeep of vital military equipment and vehicles.

- Tailored welding automation systems

- Used for land, air and seacraft

- Durable for long periods of use with minimal maintenance

Oil & Gas Applications

Welding is a critical part of the oil and gas industry. It is one of the most reliable fabrication processes that ensure the efficient functioning of pipelines, transport vessels, storage tanks, and more.

- Prevent critical weld failure

- Portable and extremely versatile

- Increase worker safety and efficiency

Power Generation Applications

Growing and changing power needs has exponentially increased the demands on contractors to fabricate wind towers, pipelines, and clean nuclear power plants.

- Increase precision & efficiency

- Perform underwater welds

- Portable for fieldwork in harsh environments

SHIPBUILDING

TANK WELDING

INFRASTRUCTURE

MILITARY

OIL & GAS

POWER GENERATION

Frequently asked questions

Find quick answers to your questions here, ask our AI assistant, or contact us for any additional inquiries.

Gullco’s automation solutions can be tailored to fit most applications. Our products are designed for flexibility and customization. To determine the best approach for your needs, please provide some details about your project. We’re happy to discuss how we can help you achieve optimal results.

Thanks for your interest in Gullco products! For accurate pricing and to discuss your specific needs, we recommend you Request a Quote and your local distributor will promptly respond.

Gullco International has presence worldwide. To locate the distributor in your area, visit our distributor locator and choose your region and location.

Absolutely! We’d be happy to schedule a product demonstration for you. Please let us know which product(s) you’re interested in and your preferred date and time, and we’ll get that arranged. We look forward to showing you how Gullco can improve your operations.

You can locate your product manual in our Resource library.

That’s a great question! We’re really proud of the ruggedness of our Gullco products. A big part of it comes from our commitment to North American manufacturing. We’ve invested over $12 million in state-of-the-art CNC equipment to ensure precision and durability. Plus, we do most of the manufacturing in-house, which gives us tight control over quality.

Ready to get started?

With over seven decades of experience and a worldwide reach, we synthesize the skills, knowledge, and experience to offer reliable, innovative solutions to automate welding and associated processes. We are committed to continual improvement, developing new welding automation systems and equipment to address the ever-changing needs of the industry.