Contents

Quick Summary: Welding tractors are automated, fully mechanized welding systems that do not need continuous human control.

Gullco International manufactures and distributes automated welding solutions across major international markets globally. We’re constantly refining our product offerings to ensure our clients have access to a diverse and state-of-the-art array of automated welding and cutting tools for use in the field and factory. Welding tractors, or welding carriages, are one of the most versatile welding solutions available on the market for any organization that needs a full range of welding capabilities at a moment’s notice. Learn more about different types of welding tractors, the benefits they offer, and how to choose the right welding tractor or weld type for your next project.

Welding tractors are automated, fully mechanized welding systems that do not need continuous human control. This equipment can accommodate MIG, TIG, FCAW, and SAM welding operations without requiring a human operator at the helm. These tools offer a high degree of weld consistency without the risk of human error, more efficient and higher deposition welds without sacrificing quality, and more cost-effective welding that can increase your profit and scale of operations.

Types of Welding Tractors

While welding tractors all feature automation and autonomous capabilities, the mechanisms they use differ. Two of the most popular types of welding tractors are self-propelled welding tractors and track-mounted welding systems.

Self-Propelled Welding Tractors

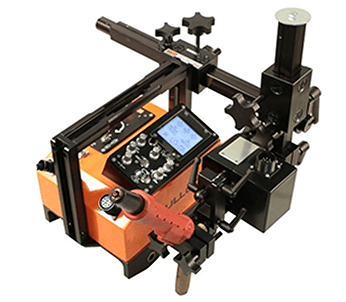

Some welding tractors are self-propelled welding systems. Unlike fully manual or hybrid systems that rely on the continuous handheld control of a human expert, welding tractors can operate a welding torch autonomously. They can be programmed to apply the right speed and torch orientation for any repetitive welding job, making them a convenient and automated solution for critical projects. Welding tractors can also fit into very small work spaces due to their compact size and autonomous operation.

Track-Mounted Welding Systems

Track-mounted welding equipment relies on an aluminum track and moves forward and backward along a rail. Each unit uses a rack and pinion system to stay on the track while facilitating movement to complete welding tasks. The rail system is very rigid and secure, which allows this system to produce extremely accurate and precise welds. Track-mounted welding tractors can create horizontal, vertical, and overhead welds.

Advantages of Using a Welding Tractor

Welding tractors offer a lot of benefits, including increased employee safety, precision, and usability within narrow confines. Three of the most valued advantages of welding tractors over manual or hybrid welding tools are:

- Efficiency: Welding tractors are extremely precise and accurate. Not only does this cut down on time and material waste for each weld, but it also ensures that there are fewer mistakes, further cutting down on waste and rework.

- Consistency: Because each movement and weld is tightly controlled by the automated system, the output is extremely consistent. Welding engineers can set the instructions, welding parameters, and conditions before the work even begins. This fine-tuned control includes indicating when the welding tractor will start and stop, the arc length, and the speed and weld pattern depending on which process is being applied.

- Portability: While some welding tractors are heavy and can be fixed in place, there are also lightweight and portable options that are meant to be taken to remote locations or used in the field. Portable welding tractors, like the KAT carriage, are used on a pipeline or at a construction site, used for general purposes in a shipyard or trailer yard and have minimal setup time and are easily moved from joint to joint.

Factors to Consider When Choosing a Welding Tractor

Already, you’ve seen the mention of a few different welding automation systems, such as self-propelled , track-mounted systems, and portable welding tractors. There are a lot of different pieces of equipment on the market, and it’s important to choose the right one. Consider the following factors:

- The position of the welds you need to frequently complete

- Accessories you might need

- The preferred type of welding process, such as flux-cored, TIG, stick, or MIG

- The anticipated applications and welding processes

What Welding Process Is Right for You?

As you consider different welding processes, start by considering the right welding process. Consider:

- The needed amperage or welding power source ‘size’ per duty cycle based on the general thickness of the metal being welded

- Whether you prefer single-pass welding or can allow for multiple passes (which may require more time and burn through more duty cycles)

Welding tractors offer more precise control of these and other welding parameters so users can increase their arc-on-time rates.

Invest in Welding Tractors From Gullco

At Gullco, we provide our clients with easy access to an array of automated welding solutions like welding tractors that are built to help them grow. Contact us today to learn more about our services or reach out today for more details. You can request a quote online or reach us at (440)-439-8333.

Relevant Resources

Frequently asked questions

Find quick answers to your questions here, ask our AI assistant, or contact us for any additional inquiries.

Gullco’s automation solutions can be tailored to fit most applications. Our products are designed for flexibility and customization. To determine the best approach for your needs, please provide some details about your project. We’re happy to discuss how we can help you achieve optimal results.

Thanks for your interest in Gullco products! For accurate pricing and to discuss your specific needs, we recommend you Request a Quote and your local distributor will promptly respond.

Gullco International has presence worldwide. To locate the distributor in your area, visit our distributor locator and choose your region and location.

Absolutely! We’d be happy to schedule a product demonstration for you. Please let us know which product(s) you’re interested in and your preferred date and time, and we’ll get that arranged. We look forward to showing you how Gullco can improve your operations.

You can locate your product manual in our Resource library.

That’s a great question! We’re really proud of the ruggedness of our Gullco products. A big part of it comes from our commitment to North American manufacturing. We’ve invested over $12 million in state-of-the-art CNC equipment to ensure precision and durability. Plus, we do most of the manufacturing in-house, which gives us tight control over quality.

Ready to get started?

With over seven decades of experience and a worldwide reach, we synthesize the skills, knowledge, and experience to offer reliable, innovative solutions to automate welding and associated processes. We are committed to continual improvement, developing new welding automation systems and equipment to address the ever-changing needs of the industry.