Arc Length System | Torch Height Control

Arc Length System | Torch Height Control

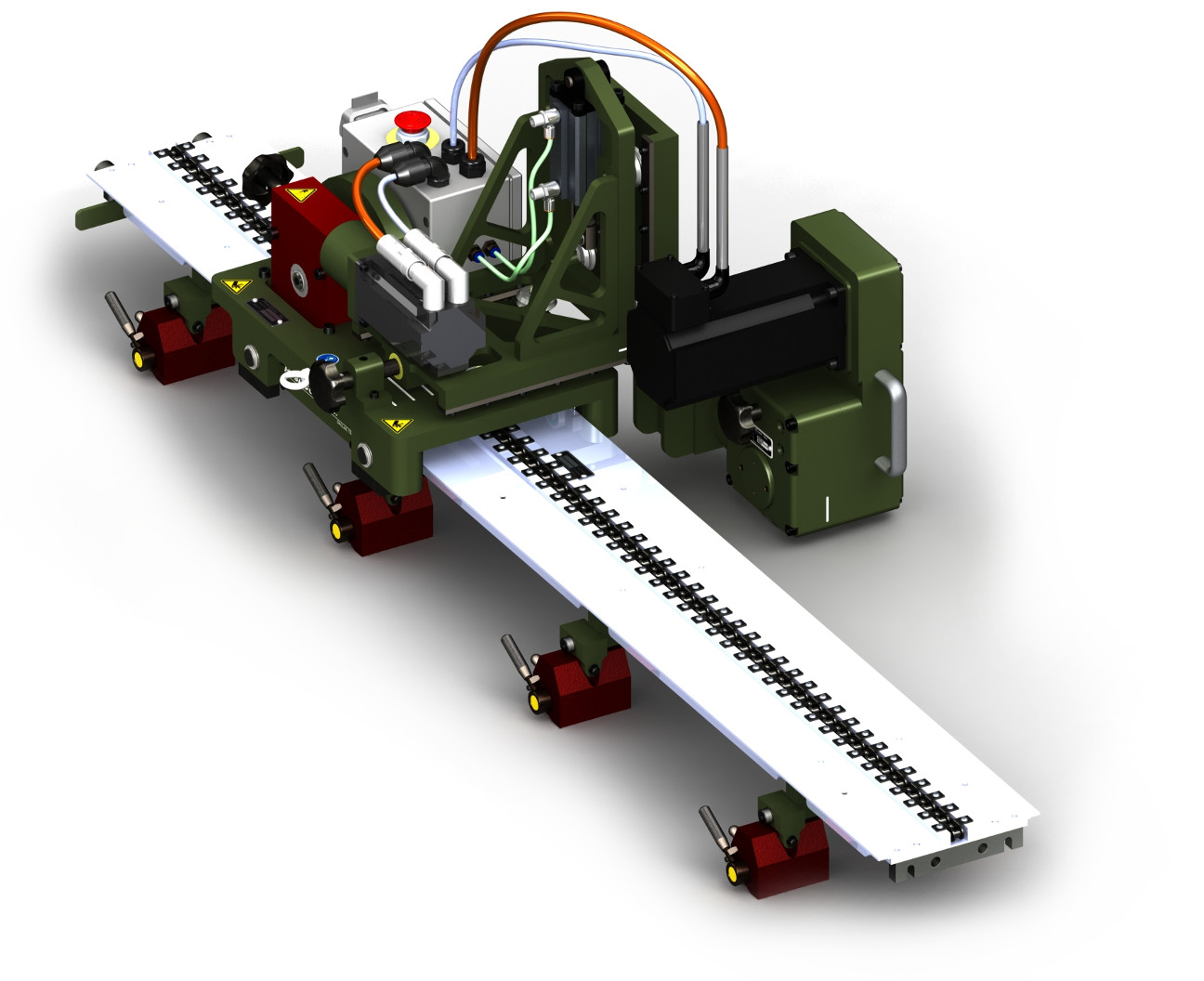

Item # TP-300-AVC — Arc Length System | Torch Height Control

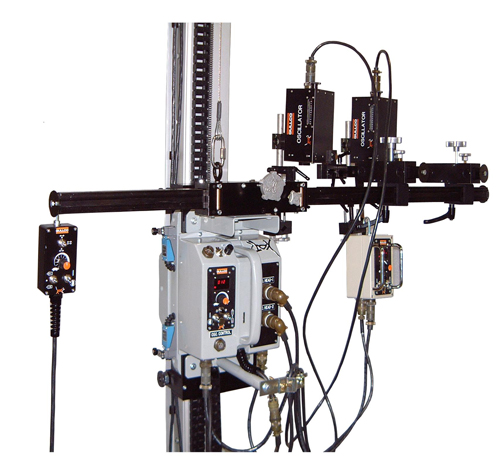

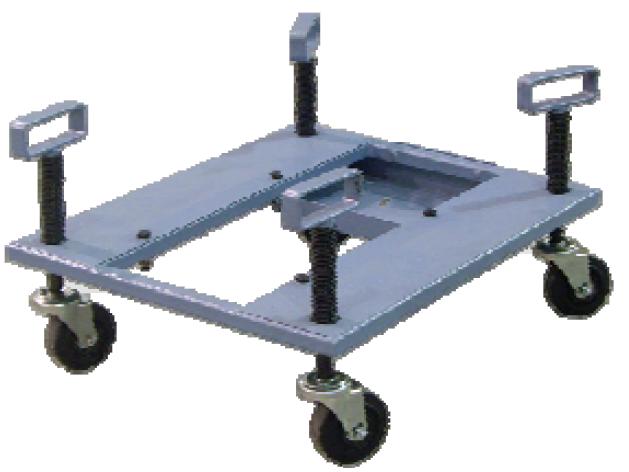

The Arc Length System (TP-300-AVC) is used in combination with TIG welding and plasma cutting power sources to give automatic control of the arc voltage to maintain arc length.

The ALS monitors the arc voltage by comparing it with the level set on the TP-300-AVC front control panel and makes changes to the torch position as necessary. Once the torch height has been selected it will be maintained despite any changes in the height of the workpiece.

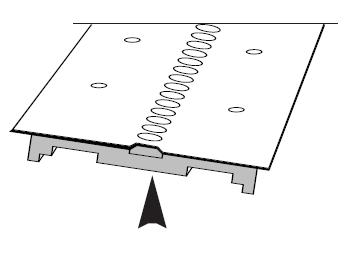

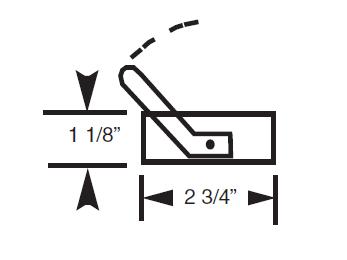

The Arc Length System can be used for DC or AC welding using TIG or Plasma cutting processes and is manufactured to be extremely durable. The linear slide is robust, needing no maintenance or lubrication, and is completely dust and dirt resistant.

Features Include:

- One unit for both TIG and Plasma applications

- Precision control of the torch positioning using the control box adjustments

- LED Digital Readout of preset parameters

- Arc Length Control Timer: Start delay can be set between 0 - 10 Seconds

- Precision control of the sensitivity and actuator speed of the corrective changes made to the arc length

- Control shows when welding current is flowing and start delay time has elapsed

- Control Box can be mounted on an Idler Carriage or stands freely on its own

Specifications:

Auxiliary supply power: 110V (105-120V) 50/60hz 1A max or 230V (220-240V) 50/60hz 0.6A max

Welding / cutting current range: 20A-400A, (max 400A@60%).

Welding voltage range: 10V-35V DC (option to set higher on request)

Cutting voltage range: 100V-350V DC

Positioner (linear actuator) voltage output: 0-15V DC (max 1A)

Positioner (linear actuator) type: DC permanent magnet

Digital meter accuracy – real value: +/- 1% +/-1 digit

Protection class IP22

Max no load (OCV) for TIG 99.9V DC (Or 120V peak)

Max no load (OCV) for plasma cutting 400V DC

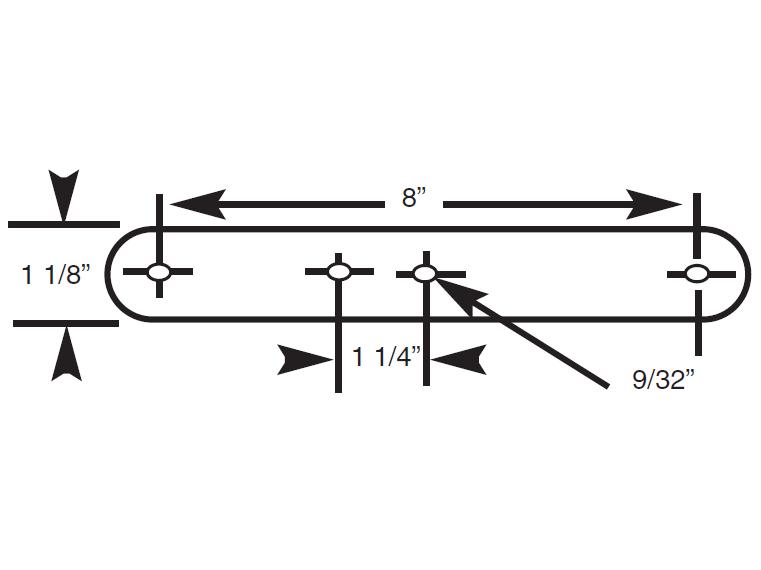

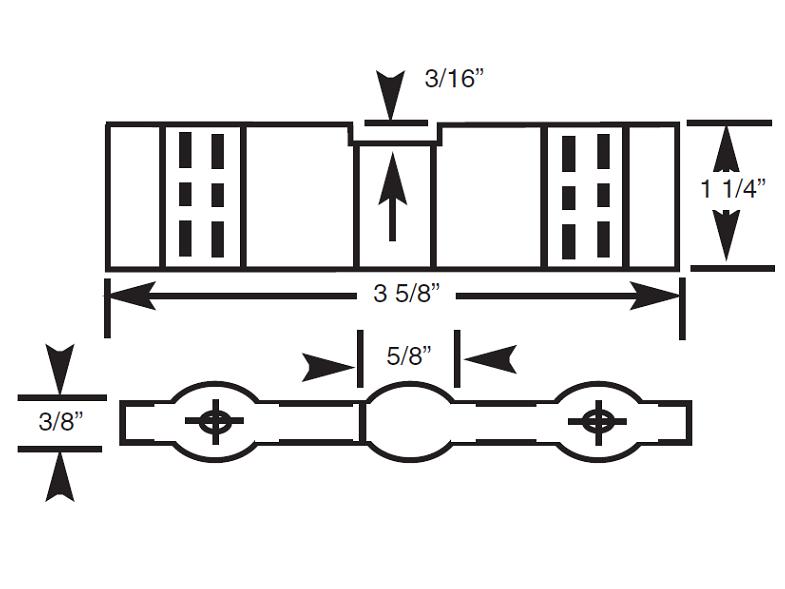

Linear Slide Range: 4”

Linear Slide Speed: 6”/min (15.2cm/min)

Linear Slide Max Load: 12lb

Related Products

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

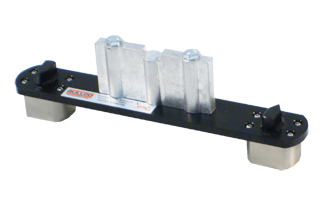

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A