Weld Positioner – Programmable and Gas Purge – 0.75 – 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Item # GPP-250-H — Weld Positioner – Programmable and Gas Purge – 0.75 – 12.5 RPM

Increase productivity, quality and profitability in circumferential welding applications

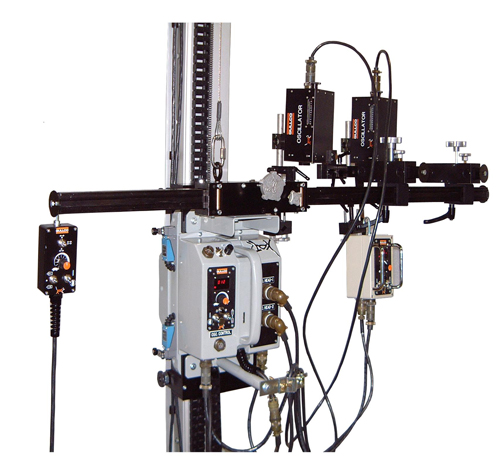

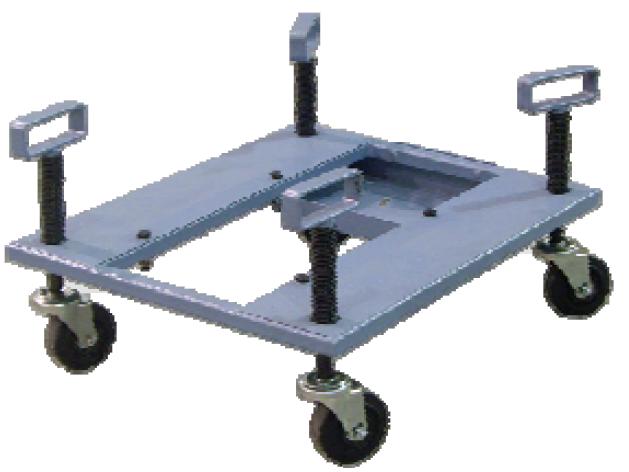

Gullco's Welding Positioner is a positive drive rotary turn table complete with mounting flange, drive and tilt mechanism and Microprocessor based pulse width modulation motor control. Standard and Programmable models are available. The welding positioner is driven by a low voltage permanent magnet motor and gearhead power unit assembly. The microprocessor motor control enables operator interface of start, stop, clockwise rotation, neutral, counter clock-wise rotation and infinitely variable control of the speed, within the range of the positioner model.

The weld positioners rotation speed is electronically controlled using an optical tachometer located on the back of the gear-motor. Speeds within the range of the model are infinitely variable in both clockwise and counter-clockwise directions through a rotary speed adjustment potentiometer located on the remote control. Table tilt is manually set at any desired angle, from 0º through 90º, quickly and easily. Safety while using the positioner is greatly enhanced with Gullco's low voltage (24 V) control and power supply system.

GP/GPP 200 Series welding positioners are available in standard or programmable models which are equipped with corresponding remote controls

The Standard Remote Control provides

- infinitely variable rotation speed within the model's speed range

- forward/neutral/reverse switch

- run/stop switch

- speed potentiometer

The Programmable Remote Control with LED readout provides

- infinitely variable rotation speed within the model's speed range

- forward/neutral/reverse switch

- run/stop switch

- programmable microprocessor providing adjustable positioning timing cycles, amount of weld rotation, weld on/weld off through 360º and a signal to activate a pneumatically operated weld gun holder and wire feed arc activation.

Purge-Equipped Models Available

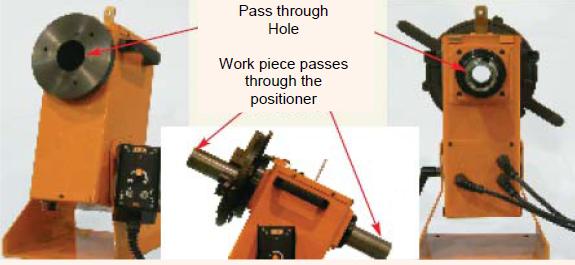

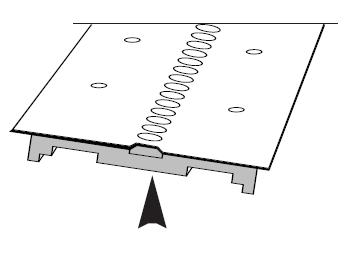

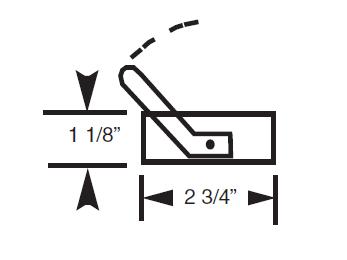

Model GP-300/350 "Through Hole" Positioner

This positioner model is designed with a 2.5 inch (63 mm) "through hole" so the work piece can be passed through the unit... making production on long pieces easier and faster.

Specifications

Specifications - Gas Purge

Yes

Specifications - Programmable

Yes

Specifications - Rotational Speed

0.75 to 12.5 rpm

Specifications - Table Rotation

Electronically controlled, infinitely variable in either direction. Positive drive.

Specifications - Table Tilt

0° through 90°

Downloads

Related Products

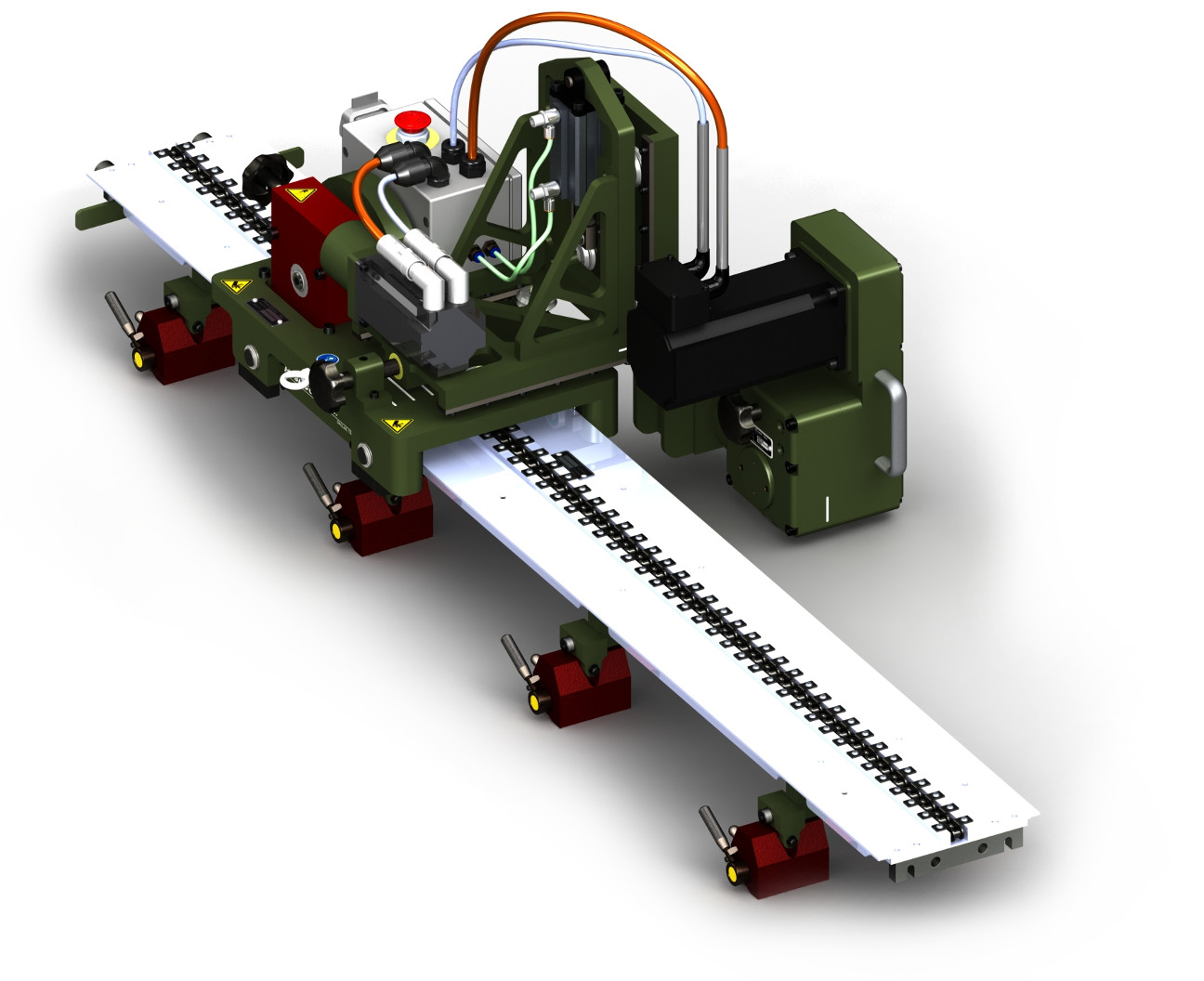

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

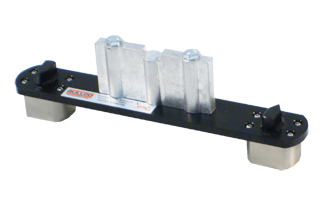

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A