KAT® Automation Carriage – Flexible Track – 0.8 – 25.8 IMP (2 – 65.4 cm/min) – 230 VAC

KAT® Automation Carriage - Flexible Track - 0.8 - 25.8 IMP (2 - 65.4 cm/min) - 230 VAC

Item # GK-200-FLC — KAT® Automation Carriage – Flexible Track – 0.8 – 25.8 IMP (2 – 65.4 cm/min) – 230 VAC

- Welding Carriage

- Programmable

- Low Voltage

- All Position

- Variable Speed

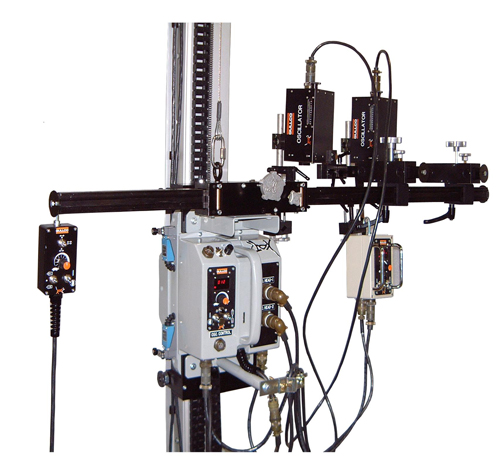

Incorporating Gullco's highly versatile "G Type" control

Reliable automation that improves quality and reduces costs in welding and cutting operations

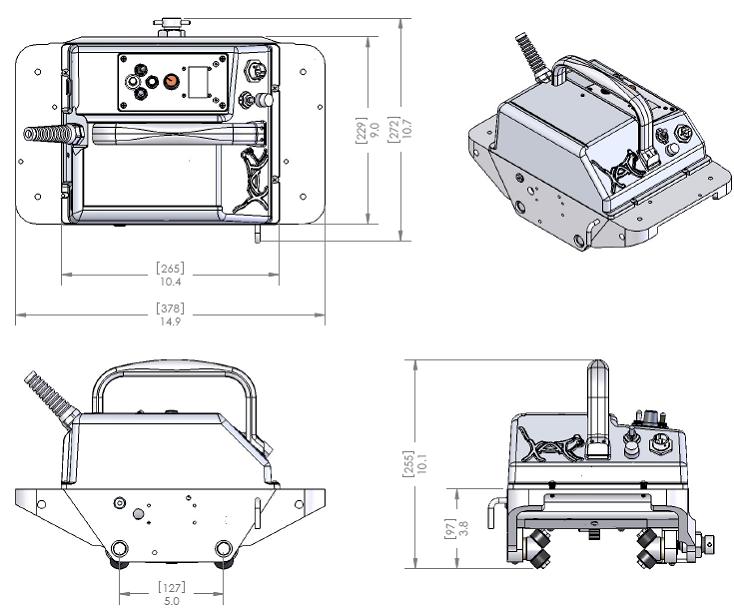

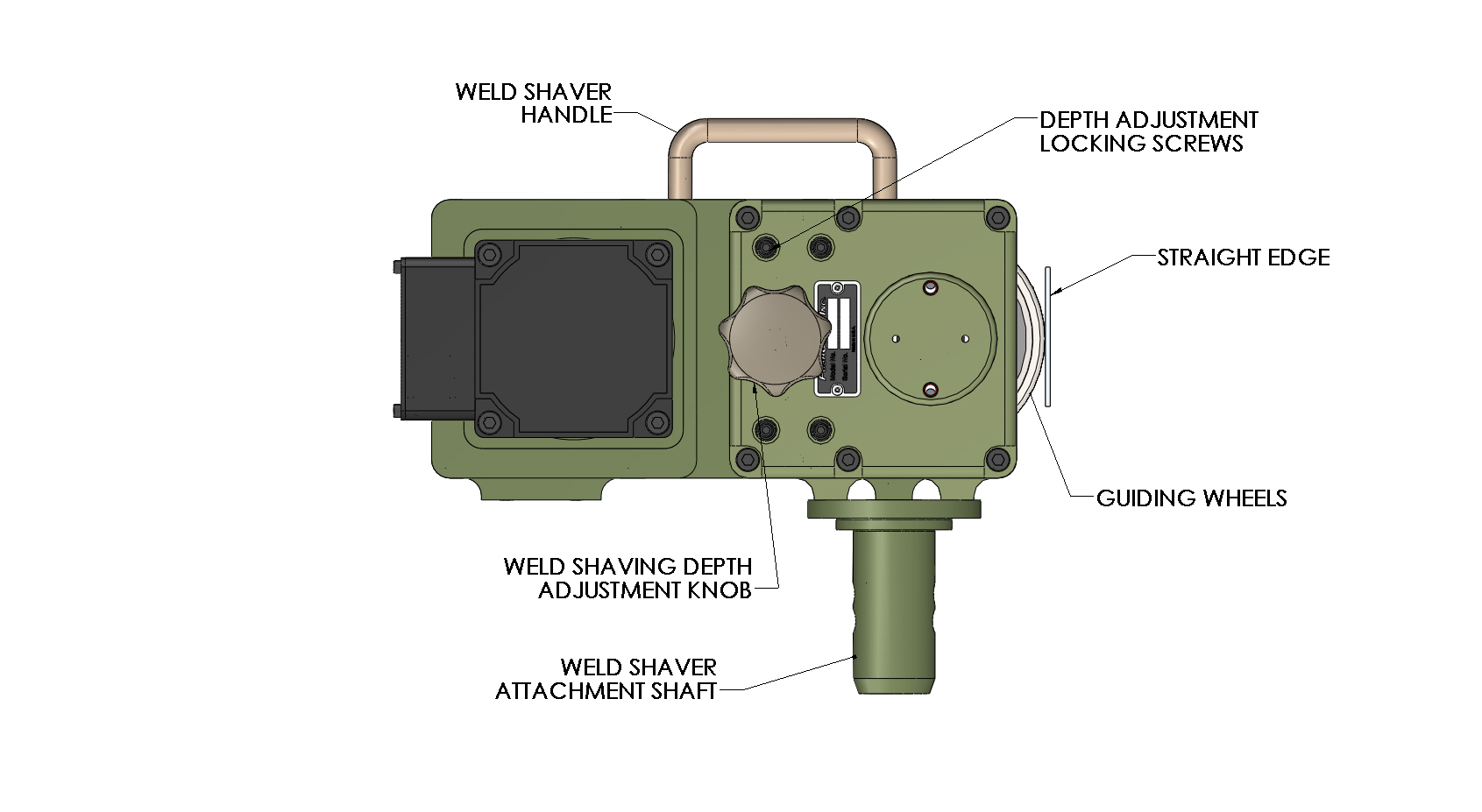

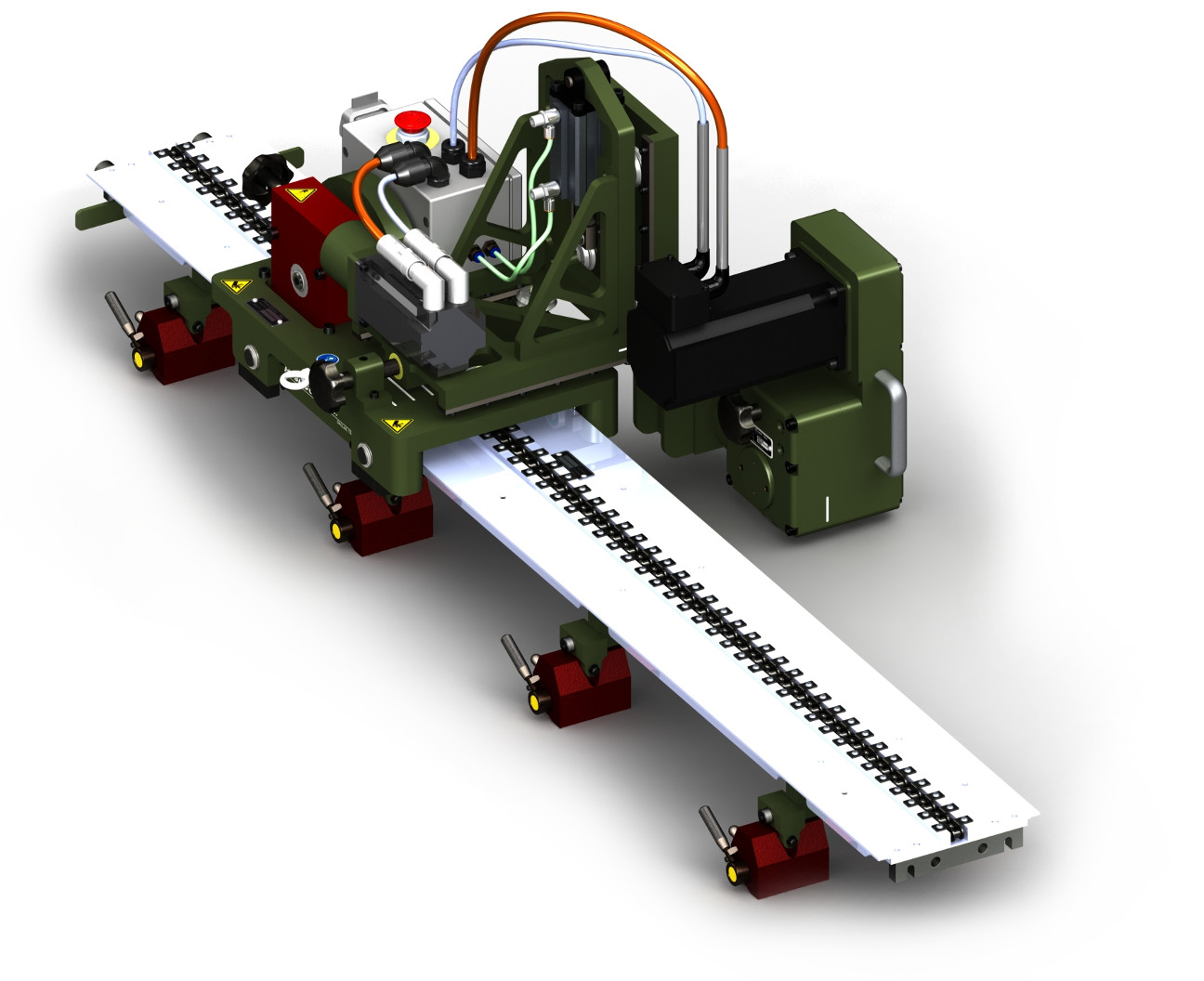

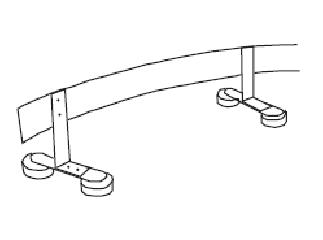

The Gullco Flex KAT® is used throughout the world to automate a wide variety of welding and cutting operations. It is a rugged, reliable precision travel carriage designed for use flexible track which enables it to operate on straight or curved surfaces along any plan Gullco manufactures several systems and accessories designed for use with the Flex KAT®...making it one of the most versatile pieces of welding/cutting automation equipment available.

The Gullco Flex KAT® carriage is used throughout the world to automate and improve the quality and efficiency of single or multiple "head" welding/cutting operations. Welding guns or cutting torches mounted on the KAT® carriage move along flexible Gullco "Flex Track" at precisely controlled speeds along the desired path in forward or reverse direction. Gullco's Flex KAT® carriage enables welding guns or cutting torches to operate with precise motion from start to finish regardless of the number of passes or the work pieces involved, improving the quality, efficiency and repeatability of the process. Poor or awkward accessibility, operator fatigue, or inconsistent workmanship are eliminated.

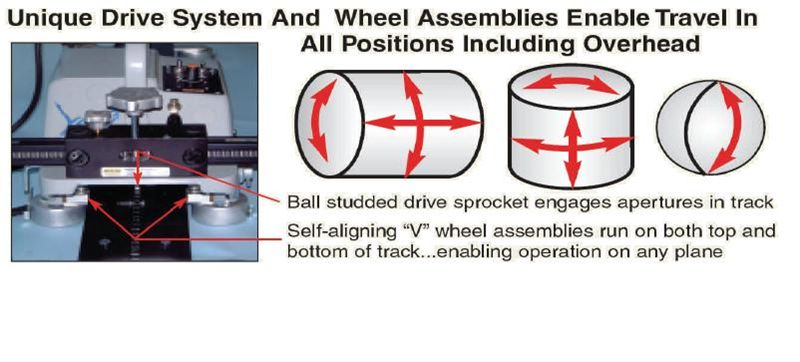

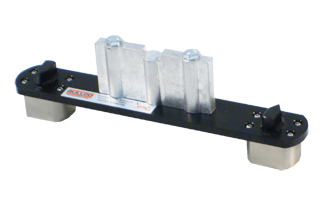

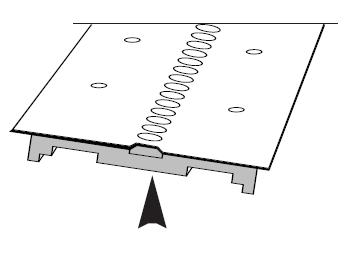

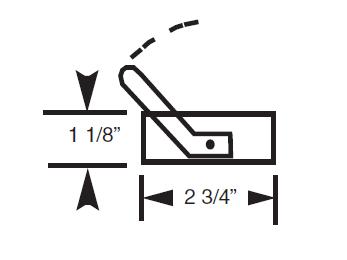

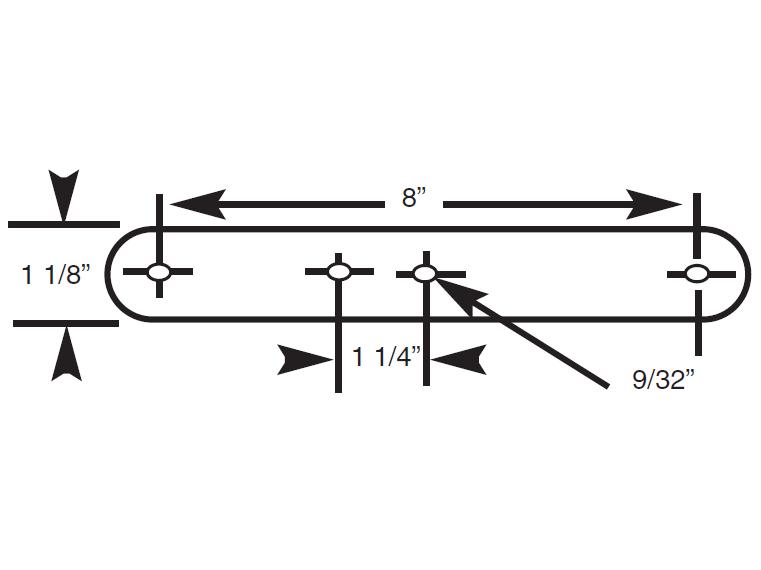

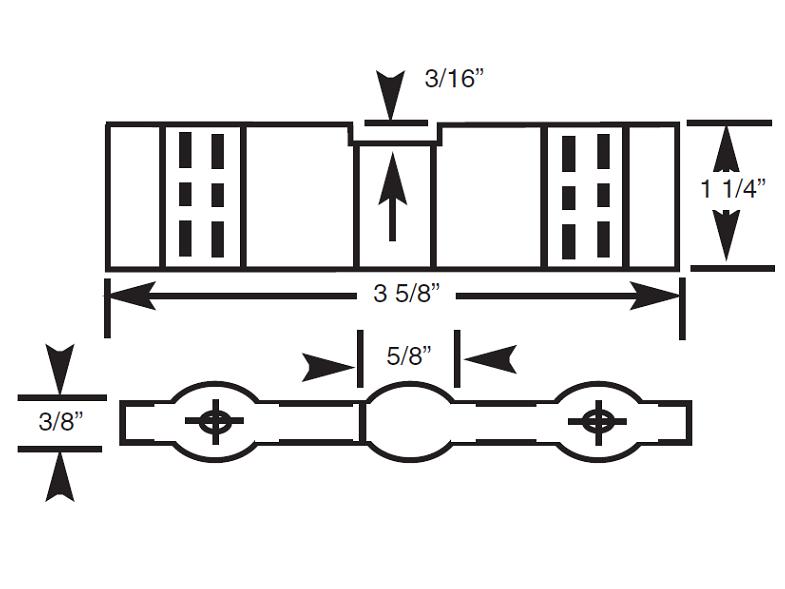

This unit is designed for operation on curved surfaces as the flexible track can be positioned to follow the contour of the workpiece. The self-align ing wheel system of the carriage grips the top and bottom of the track, enabling it to travel along any plane. The adjustable wheel assembly keeps the carriage snug to the track, while allowing it to be easily mounted and removed from the track at any point. The positive drive of the KAT® is obtained from a uniquely designed sprocket that engages with slots in the track, driven by a low voltage permanent magnet motor and gear-head power unit assembly.

Specifications

Specifications - Model

FLC

Specifications - Input Supply

230 VAC

Specifications - Option

Carriage options must be selected

Specifications - Drive Motor

24 VDC permanent magnet gear motor

Specifications - Supply Voltage

42, 115 or 230 VAC, single phase, 50/60 Hz., 200 watts

Specifications - GSP Control

The Gullco Standard Platform range of controls have switching for forward/neutral/reverse, run/stop, Manual/Auto & program variable increment/decrement (where applicable) and a rotary encoder for speed control. This micro-processor based, 24 volt DC motor control can be supplied to provide a variety of "optional" functions such as indexing, weld oscillation and auto-weld. The selected "option" function and carriage travel speed/direction are directed by a single GSP control. This ensures high levels of accuracy, quality and reliability.

Specifications - Complies with

C.S.A. & CE Certification

Downloads

KAT - Flexible Track Carriage.pdf

KAT - Flexible Track Carriage.pdf

Parts List

Parts List

KAT® - Flexible Track

KAT® - Flexible Track

KAT All Position Welding Video

KAT All Position Welding Video

KAT Carriage Cutting Video

KAT Carriage Cutting Video

KAT Flex - Operation Manual

KAT Flex - Operation Manual

KAT - Flexible Track Carriage.pdf

KAT - Flexible Track Carriage.pdf

Parts List

Parts List

KAT® - Flexible Track

KAT® - Flexible Track

KAT All Position Welding Video

KAT All Position Welding Video

KAT Carriage Cutting Video

KAT Carriage Cutting Video

KAT Flex - Operation Manual

KAT Flex - Operation Manual

Related Products

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A