KAT® Weld Indexing Carriage – Rigid Track – 0.5 – 16.4 IPM (1.2 – 41.6 cm/min) – 42 VAC

KAT® Weld Indexing Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 42 VAC

Item # GK-200-RLA-I — KAT® Weld Indexing Carriage – Rigid Track – 0.5 – 16.4 IPM (1.2 – 41.6 cm/min) – 42 VAC

Automates Overlay/Cladding Welding Operations

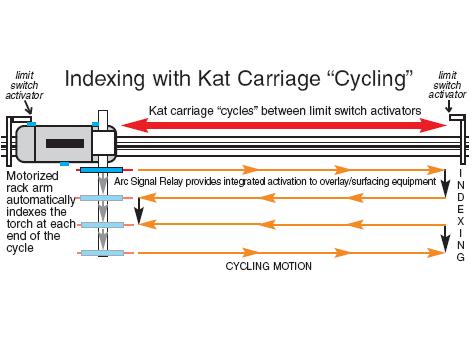

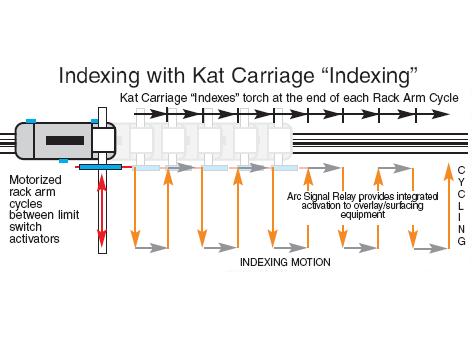

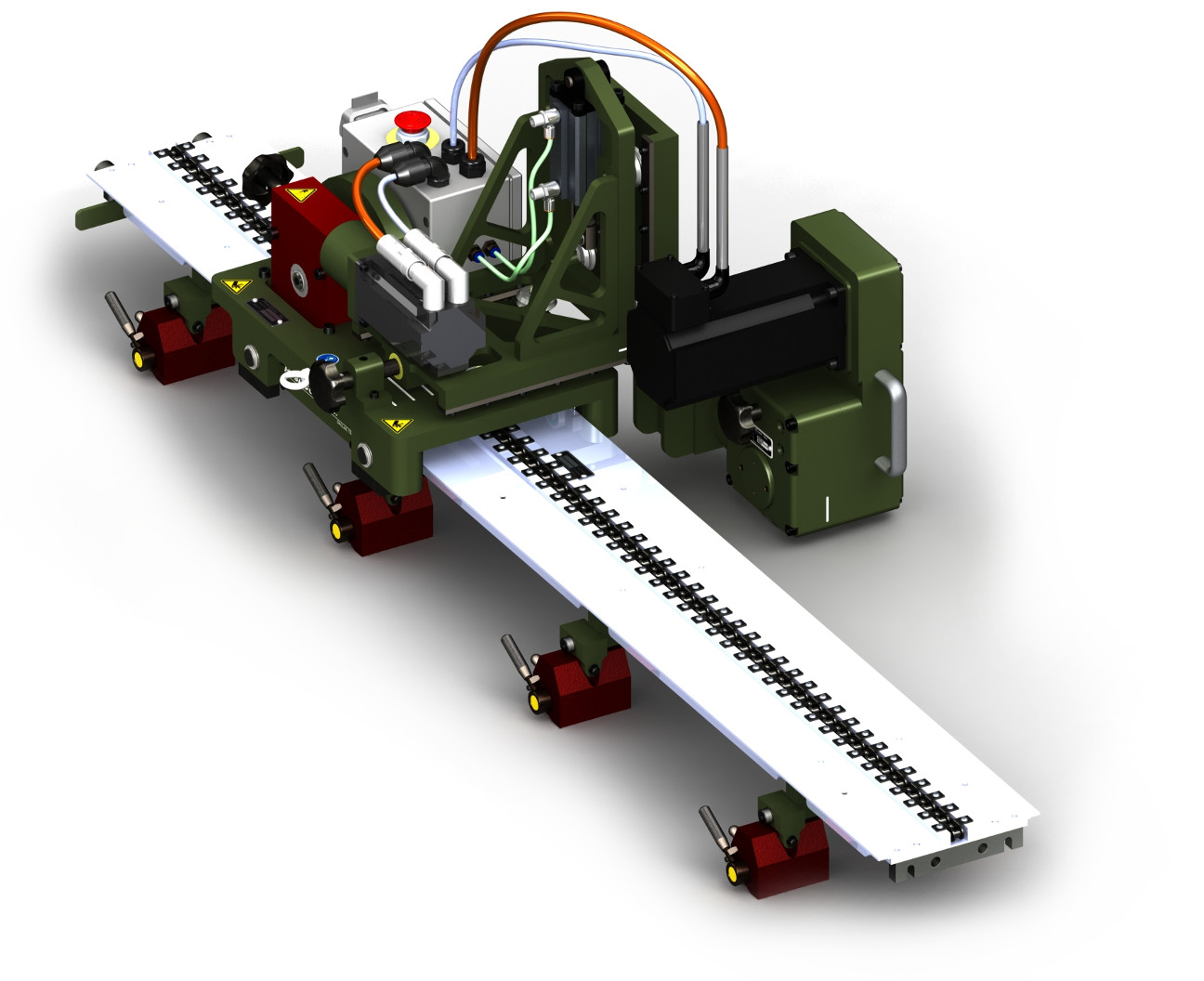

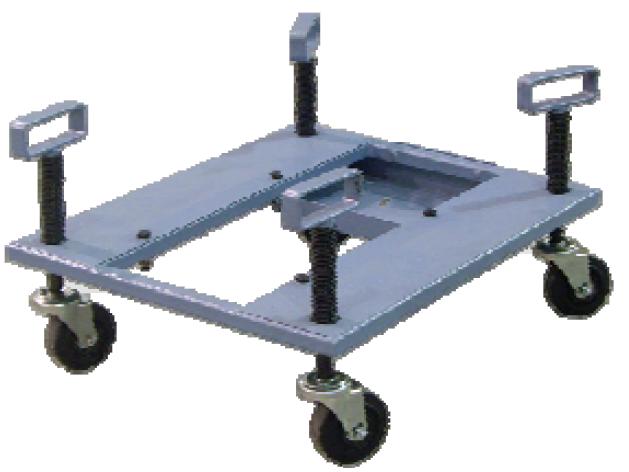

The Gullco KAT®Indexing System is typically used to automate single or multi-head overlay/cladding welding operations, hard surfacing, etc. The automatic routine drives a motorized device (either the KAT®carriage or the motorized rack arm), cycling back and forth between limit switches. When the device that is cycling reaches a limit switch, it pauses, and the other motorized device starts to index the gun/torch a preset distance in a preset direction. An Arc Signal Relay is supplied with the system to provide integrated arc activation signals to the overlay/surfacing equipment. Two GSP controls, each with dedicated microprocessor chips, are used to control the automatic, two axis indexing system. One GSP control is the Cycle Control and the other is the Index Control. Each control offers user programmable parameters/variables to allow fine-tuning and functional control of the automatic cycle. Gullco Indexing Systems, enable repetitive overlay/ surfacing cycles to be preformed, with precise motion of the gun/torch from start to finish, regardless of the number of passes of the work pieces involved.

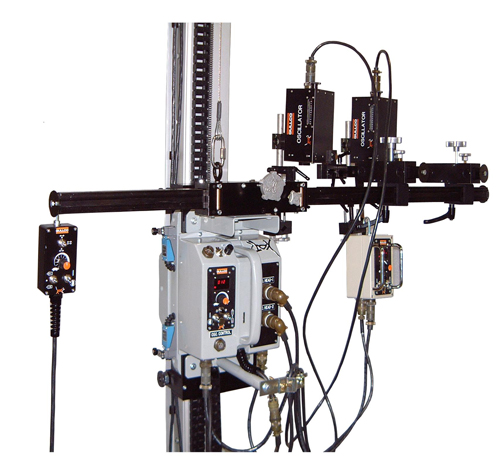

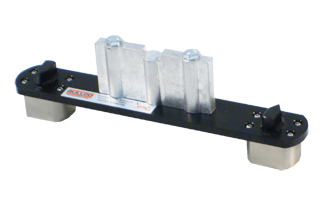

Main Components: KAT®Travel Carriage (Flex KAT®for use on flexible track of Rigid KAT®for use on rigid track), KAT®Carriage/Indexer controls, Motorized Indexer Rack Box, Heavy Duty Rack Arm, Control Cable, Limit Switch activators for Carriage and Rack Arm, Torch Holder for standard MIG gun.

Controls: Two GSP controls mounted in the KAT®, each with dedicated microprocessor chips, are used to control the automatic, two axis indexing system. One drives the KAT®, carriage; and one drives the motorized rack arm. They provide: Auxiliary wire feeder on/off, 16 Position Switch giving selectable index increments, Maximum travel of 24" (609 mm) using 36" (914 mm) long rack arm, Two Digit Display indicating time that rack arm will index, KAT®Carriage Forward/ Reverse Switch and Carriage speed potentiometer, rack arm Jog Switch and Left/Off/Right switch, Auto On/Off switch, LED display.

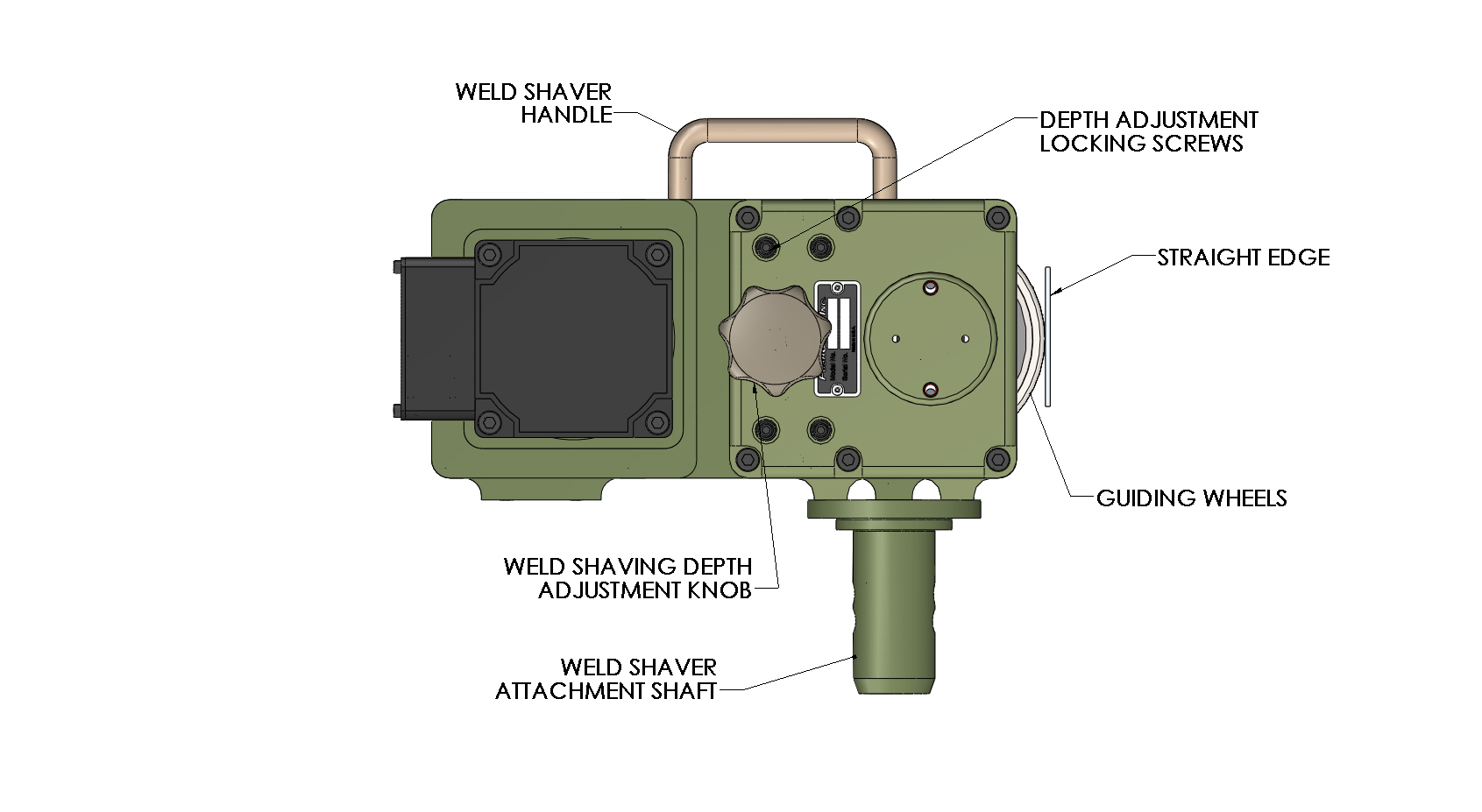

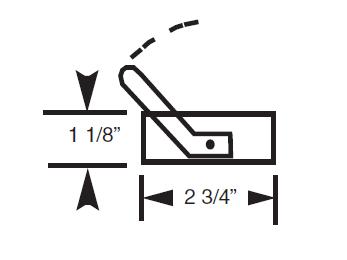

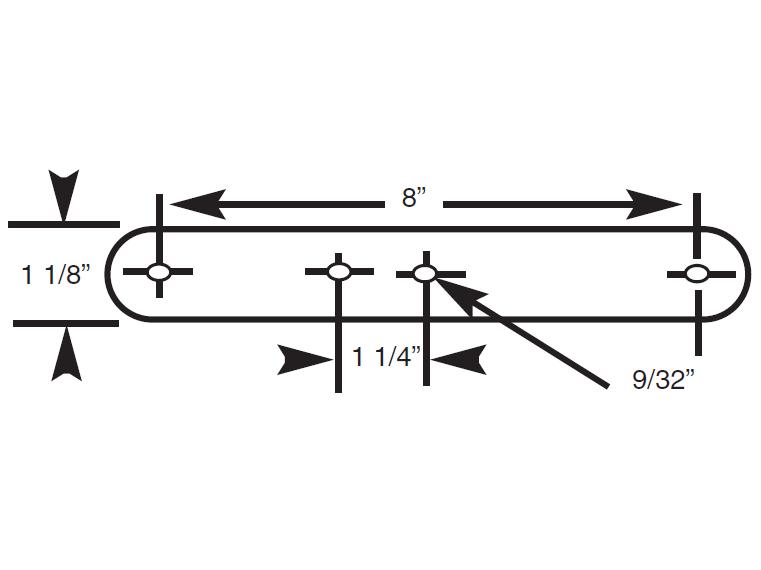

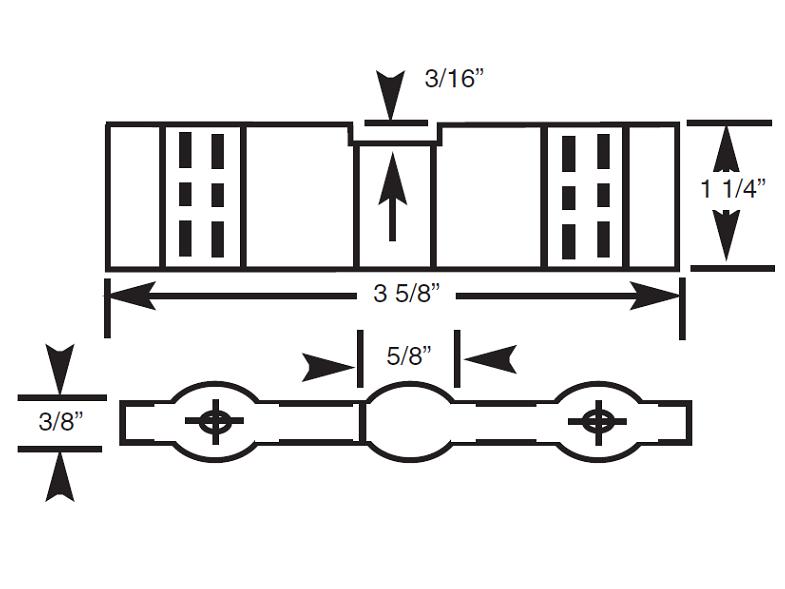

Indexing Motorized Rack Box: Complete with limit switches and activators to prevent rack arm overrun, high torque gear motor to provide precise repeatability of the rack arm indexing distance. Standard assembly combines heavy duty 8" (203 mm) long rack box with 1-1/8" (29 mm) sq. x 36 (914 mm) long rack arm. Other lengths available

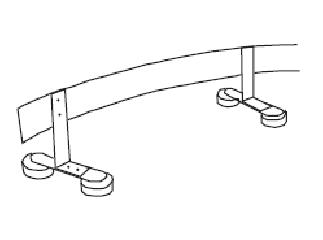

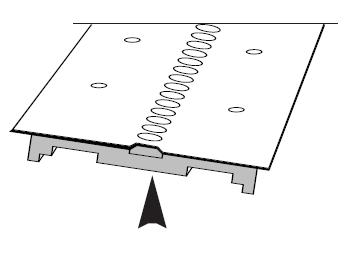

Flex or Rigid KAT®Travel Carriage: with microprocessor pulse width modulation motor controls offering operator interface of forward, stop, reverse and infinitely variable control of the speed, within the range of the models. Travel speeds of the KAT®and Rack box are electronically controlled using an optical tachometer on the back of each gear-motor. Through the use of this closed loop, feedback circuitry, each motor control can obtain accurate and constant speed control of the equipment when running in any plane, regardless of the load (within the rating of the equipment). The length of the KAT®travel path is pre-set by positioning the Track Stops at each end of the desired path. They engage and activate limit switches on the KAT®Travel Carriage to: automatically stop the travel carriage and reverse its movement, activate the control that indexes the rack arm and signals the welding gun to weld or not weld during indexing.

Safety is greatly enhances by the use of Gullco's low voltage (24V), highly advanced controls and power supply system. Three line voltage inputs, 42, 115 and 230 VAC, single phase, 50/60 Hz, are available.

Specifications

Specifications - For Use On

Kat Rigid Track

Specifications - Input Supply

42 VAC

Remote Pendant Control Kit

...for use with Rigid/FlexKat Auto-Weld systems.- Comprising Remote Pendant (no control)attached to 8 ft (843.84cm) control cable one end and KAT control blanking plate other end with internal connectors at each end. This remote pendant uses the GSP control removed from the "KAT" Carriage. This kit can be easily field installed (or factory installed at no charge)

Remote Control Indexer for Miscellaneous Rotation Equipment

Comprising of one (1) control box with switches for rack arm jog, cycle start and speed potentiometer. Index distance setting in a range from 0.01 to 9.99 in increments of 0.01. A single limit switch on 15 feet (4572 mm) cable to provide 1/8" (29 mm) rack arm 36" (914mm) long providing 24" (609 mm) of variable speed arm travel 1 to 32.7" (25 to 83.1 cm) per minute with limit switches to prevent rack arm over-travel and to stop wire feeder. Two (2) adjustable rack arm limit switch stops and one (1) four-motion welding gun holder.

Downloads

Related Products

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A