3 Items Added to Quote

View Quote CartPipe KAT® - Flexible Track - 230 VAC

Item # PK-200-C — Pipe KAT® – Flexible Track – 230 VAC

- High Deposit Rate

- More Arc On Time

- Easy To Use

- Quick Setup Time

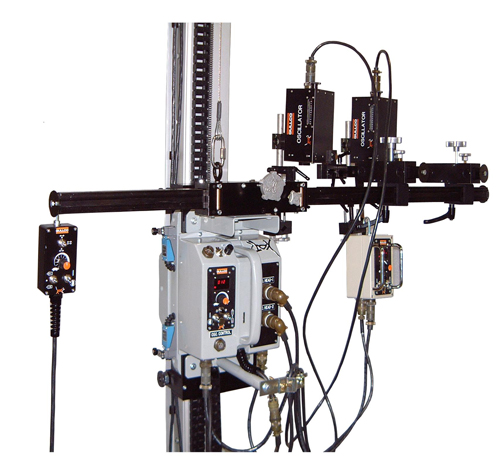

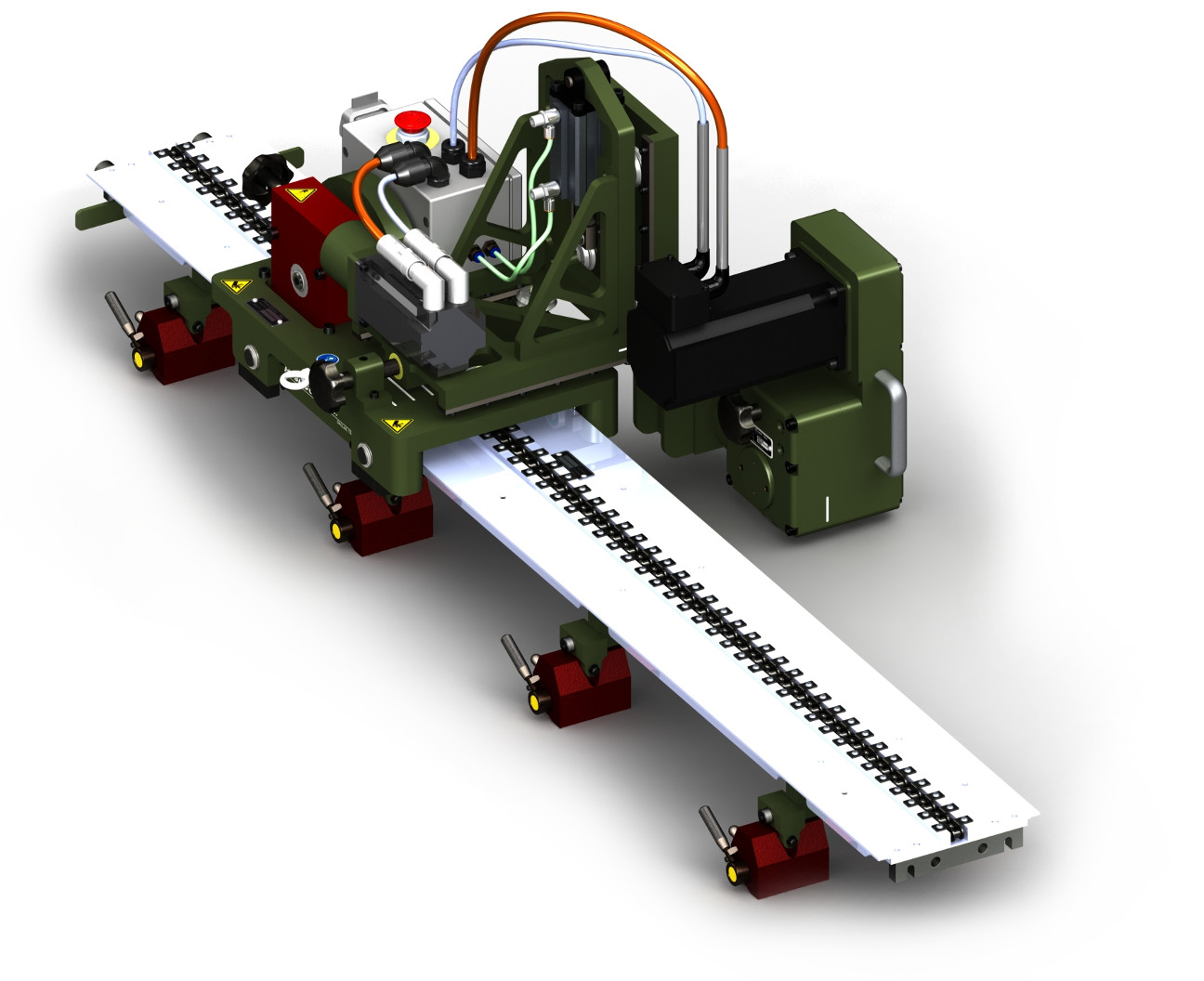

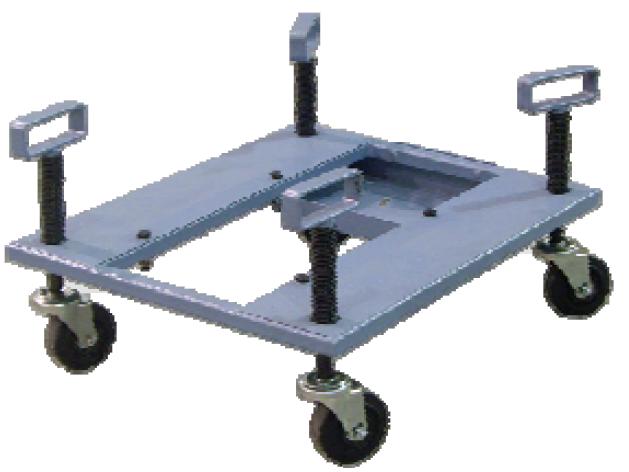

Gullco PIPE KAT® Automated Pipe Welding System with integrated wire feeder unit incorporates 40 IPM welding carriage design with quick action mounting for ease of installation. The carriage is equipped with a high speed return feature for faster repositioning of the carriage. The PIPE KAT® also comes equipped with a linear oscillator with adjustable weave width and weld joint centerline adjustment and all electronic motorized functions incorporate jog settings. The system comes with a main control box with 25 ft (7620 mm) umbilical, wire feed spool capacity of 10 lbs (4.5 kgs), with a maximum wire speed of 35-633 IPM (89-226 cm/min) and a wire size range of 0.8 to 2 mm. The welding torch uses Abicor Binzel consumables.

The Gullco Pipe Kat is a practical, affordable alternative to manual welding of larger diameter and heavy wall pipes. It produces x-ray quality welds at 5 to 15 times the deposition rate of GTAW. Robotic consistency and precision make it ideal for pipeline site use or industrial shop areas. The Pipe Kat’s versatility allows it to be powered by a variety of power sources.

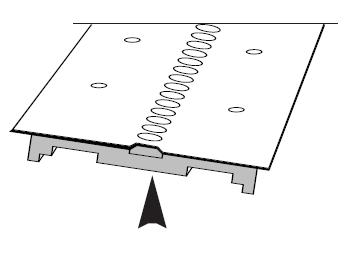

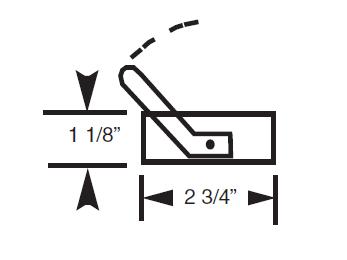

The Head unit is mounted on the pipe by means of a quick mount metal guide ring, which is available for all standard and most custom pipe sizes. The weld head unit mounts entirely on one side of the joint, providing full open access to the weld joint area. .

The Pipe Kat’s unique design allows it to weld pipes as small as 14” up to and including flat horizontal or vertical welding. For a more precise control over the welding process the Pipe Kat is equipped with our newest linear Oscillator. This allows the operator to control the direction, wire feed jog, carriage speed (0-40 IPM /1016mm/min ) as well as motorized centerline positioning and motorized width adjustment. By combing all of these features in to one easily used remote controlled pendant the operator has the freedom to move around the carriage and inspect the weld in real time with the ability to make minor or major adjustments to the welding process at the push of a button. .

Gullco’s Pipe Kat uses the Flux Core Arc Welding (FCAW) process and is compatible with all material where flux core wire can be used. With the Pipe Kats unique design it is able to weld any pipe regardless of its wall thickness. This allows the Pipe Kat to be adapted to fit any pipe project.

Related Products

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A