Kat Track is manufactured in “Standard” and “Deep” sections...each designed to suit a specific range of applications. Both are made to the highest quality levels and incorporate the following top performance features:

- Precision Extruded Aluminum Track - made from aluminum that is solution heat treated and artificially aged to produce an alloy having excellent mechanical and corrosion resistant properties. The track is

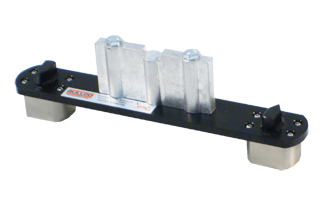

light but strong and the standard section can be readily formed to suit the work contour. - Supporting Steel Rack - is securely fixed to the Kat track to provide a smooth, positive drive. The long-life rack easily supports the Kat carriage under maximum load when used in a vertical plane.

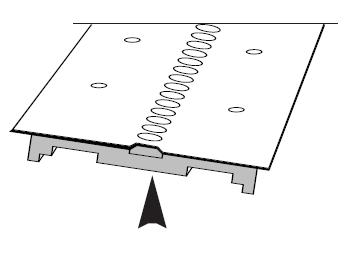

- Interchangeable End Design - enables any two lengths of track to mate accurately and, because of symmetry of design, track lengths can be turned end to end. It is even possible to mate standard and deep track sections.

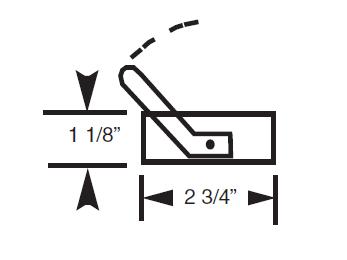

- Fast, Easy Joining - with combined dovetail and taper screw that provides accurate location between mating track lengths. The track can be joined in the time it takes to tighten two knurled thumb screws.

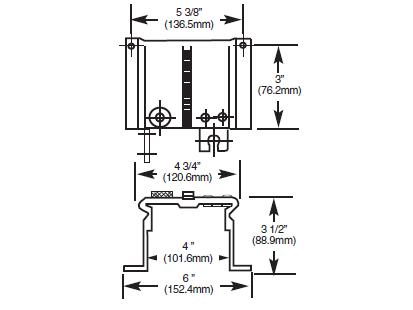

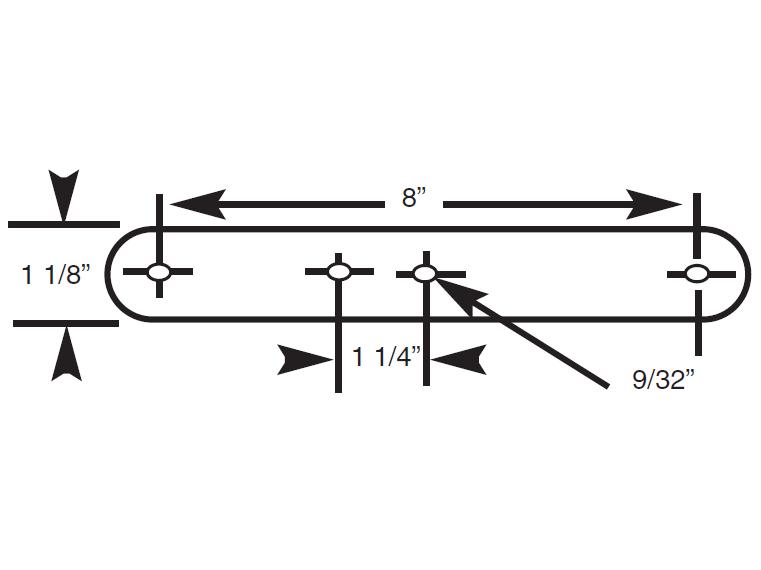

- Versatile Mounting - Both standard and deep section tracks have fixing holes on 6" (152.4 mm) pitch along their entire length to provide ample means for mounting or securing brackets.

Also Available...Custom Formed Ridig Track

Gullco provides complete Kat Track forming services to customer specifications. Contact Gullco for detailed information.

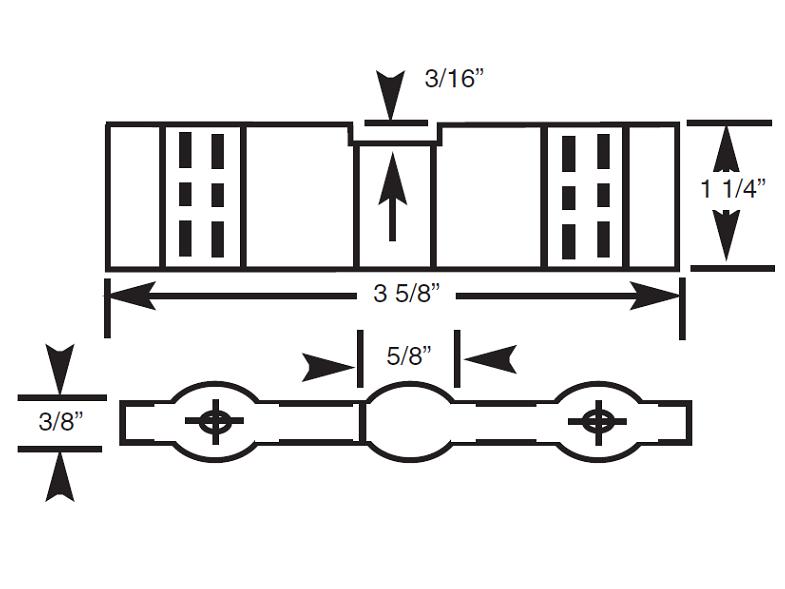

For use with the Gullco Kat P-Type Travel Carriage in applications involving straight permanent runs where greater stiffness is required. Supplied in 60” and 120” (1524 and 3048 mm) lengths complete with interlocking end connectors and fishplates. Deep Section Track can also be supplied internally stiffened and hard anodized.

Specifications

Specifications - Type

Deep Section Track

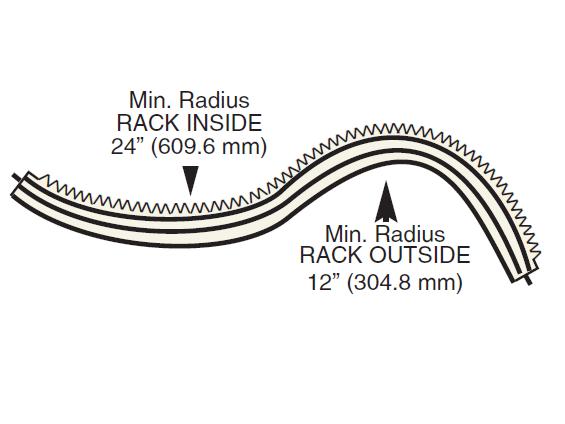

Forming Standard KAT Track

The following information is provided as a guide to customers

ordering Standard Section track pre-formed to the desired

contour by Gullco, or to be formed in their own shop.

1. “Track Datum” always refers to the track surface to which

the rack is fixed.

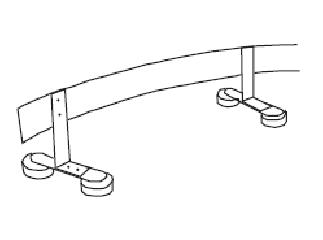

2. When the rack is on the outside of the curve, the “Track

Datum Radius” must be greater than 12".

3. When the rack is on the inside of the curve, the “Track

Datum Radius” must be greater than 24".

4. Always specify whether rack is on the inside or outside of

the curve.

5. Standard formed track lengths are 3 ft. and 7 ft. This is

because the first 6" at either end of a track cannot be formed

and is therefore removed after bending.

6. When calculating the “Track Datum Radius”, allowance

must be made for the method of fixing the track to the work.

The minimum allowable work to “Track Datum” distance (to

permit free movement of the “KAT” carriage) is 1-1/2" and

when using the standard magnet assemblies

this distance is 2-7/8".

“KAT” formed track may be held in position by the

usual track mounting devices (i.e. magnets, steel

brackets tack welded in position, or vacuum cups), or it may

be permanently attached to framework alongside the workpiece.

If your formed track is of a very permanent nature, it is often

advisable to have a section formed and stiffened with welded

aluminum side plates. This gives the stiffness of a deep

section track in a formed shape. This method is often used

in complete ring sections for cutting or welding large

diameter pipes.

Specifications - Length

120 in

3048 mm

Specifications - Weight

3 lb/ft

4.5 kg/m

Downloads

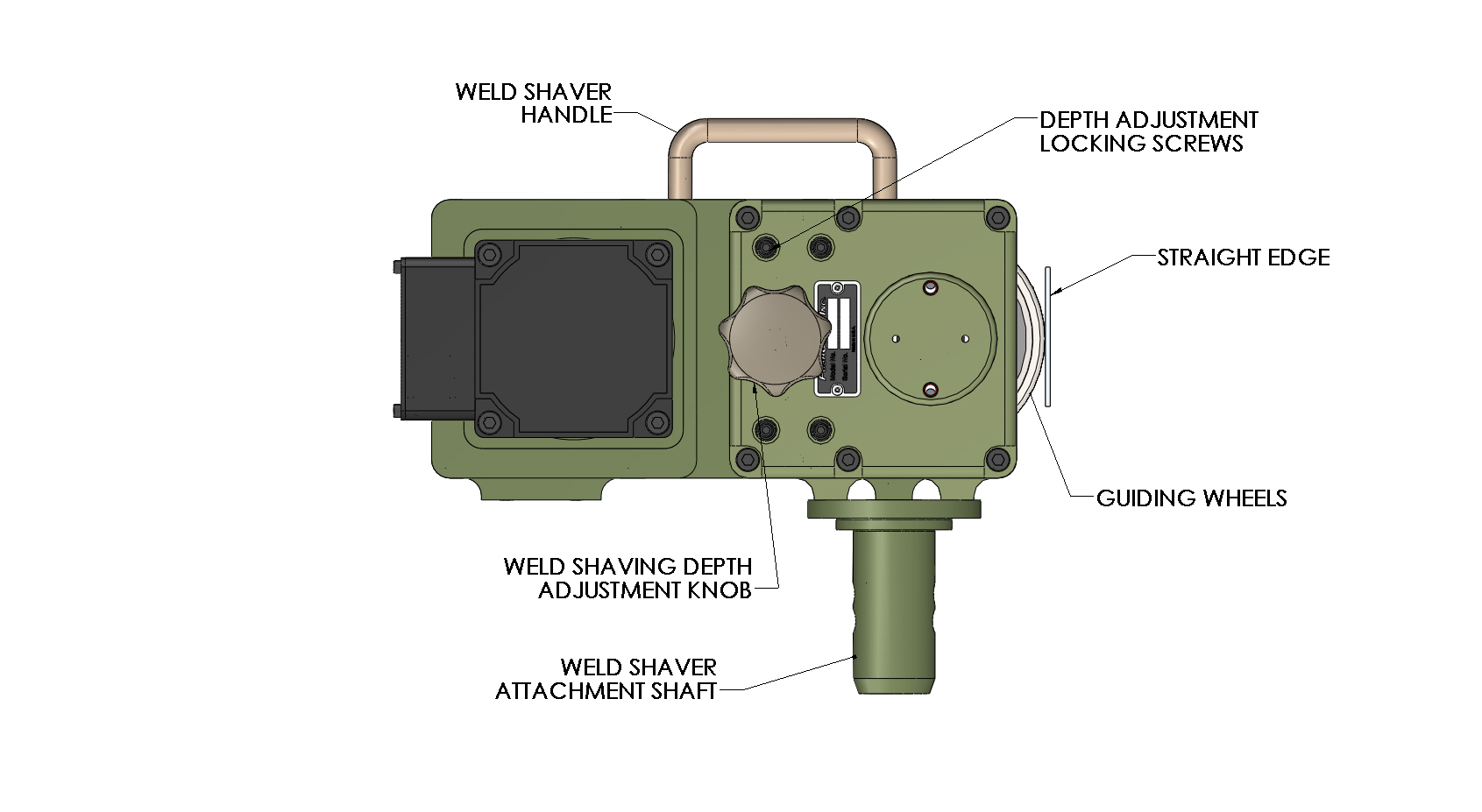

Related Products

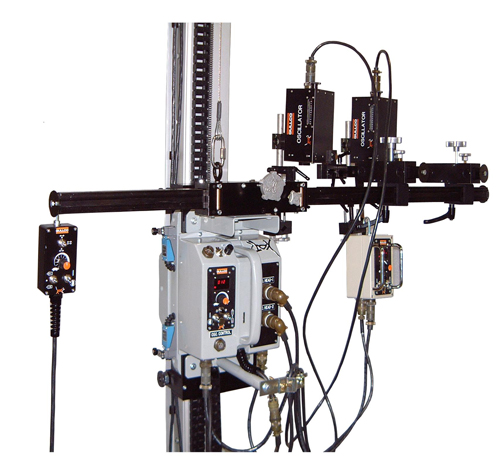

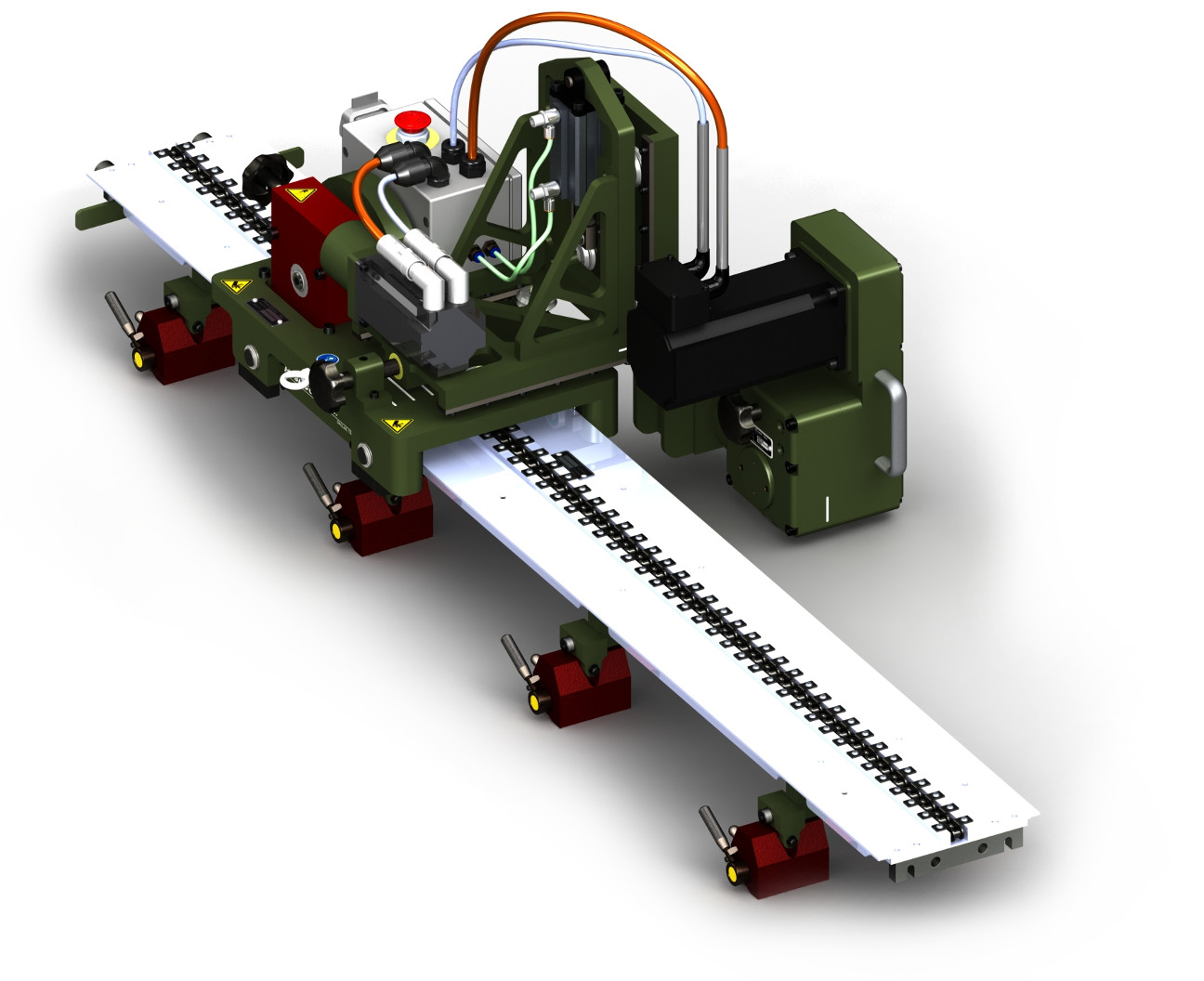

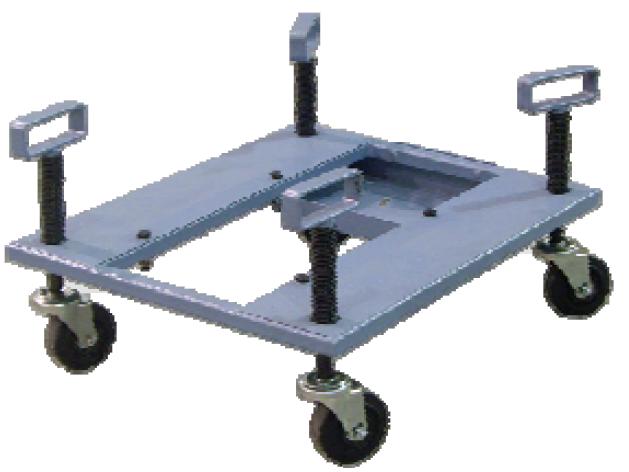

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A