Automatic Rotary Weld System

Item # Automatic Rotary Weld System — Automatic Rotary Weld System

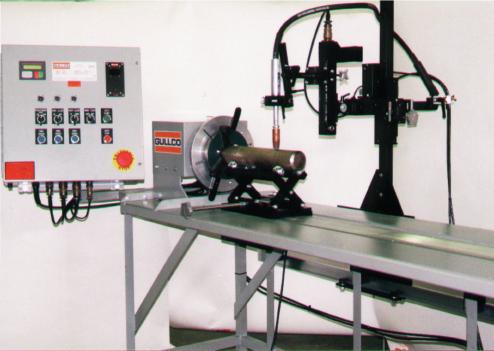

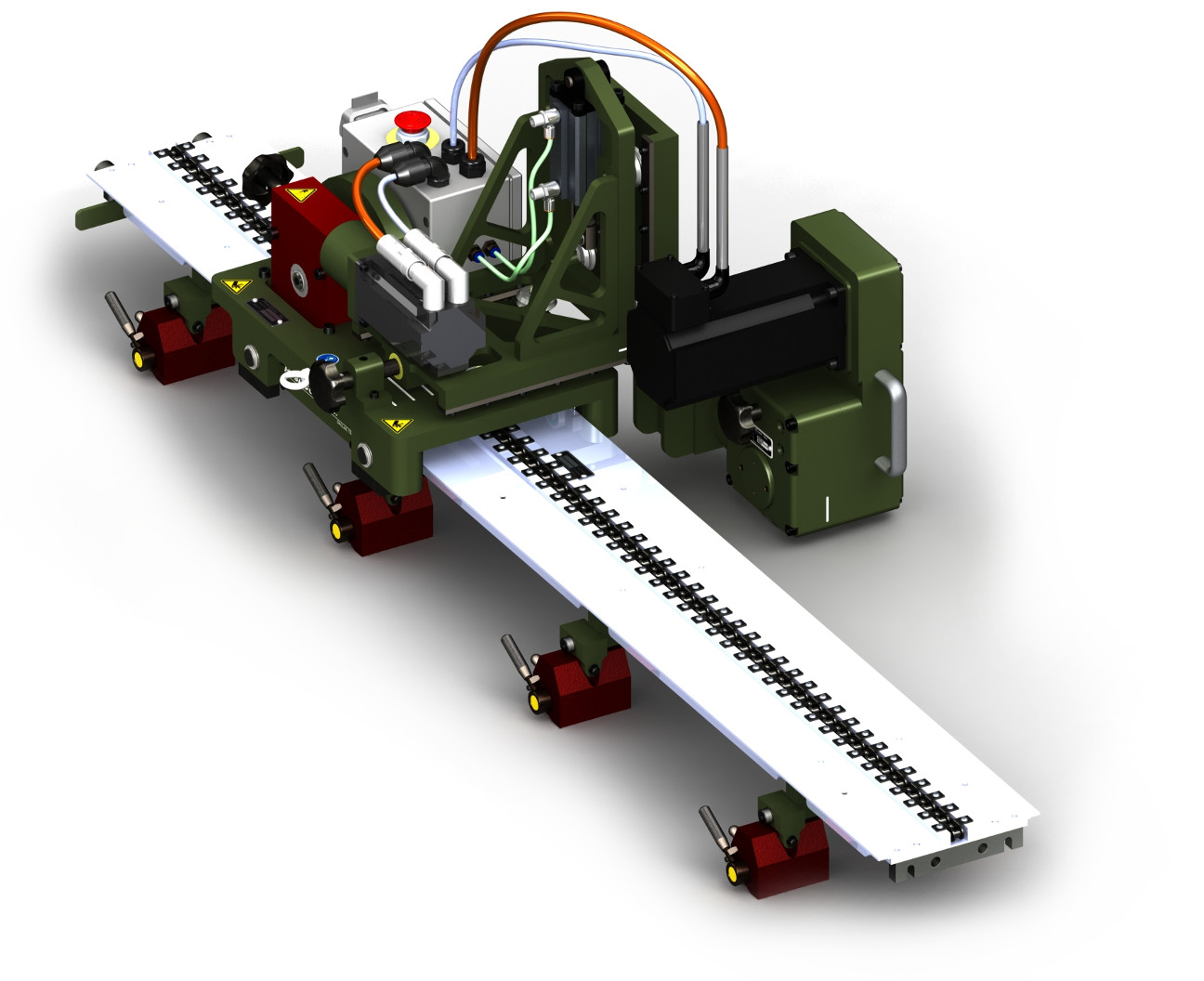

Automate your circumferential welding operations and add efficiency and increased precision with the highly flexible Gullco Automatic Rotary Weld System.

- rotary weld table with tack feedback interfaced with a PLC...providing precision stop/start, weld stop/start, adjustable rotation speed, weld overlap, multipass welding and tack welding

- accurately adjustable tailstock with 6" (152mm) pneumatic clamping slide

- motorized torch positioning slide...enabling quick and easy loading/unloading of the workpiece

- maximum weight capacity 300 lbs (136kgs)

- table lengths up to 20 ft (6096mm)

Ideal for automating production of flanges, cylinders, end caps, valve components and other cylindrical parts.

The Gullco Automatic Rotary Weld System is a low cost automated welding machine that produces consistent, precision welds on cylindrical workpieces. It is designed to provide reliable quality welds, either in high or low production. It is easy to operate while providing sophisticated operational flexibility.

The Gullco Automatic Rotary Weld System comes complete with...

- Gullco programmable Motor Control interfaced with a PLC providing adjustable rotation speed, rotation stop/start, weld stop/start, wire feed stop/start and emergency stop controls, LED display for all functions

- Headstock...full 360° rotation with adjustable overlap, precision controlled electronically

- Multipass Welding...available with automatic torch height adjustment

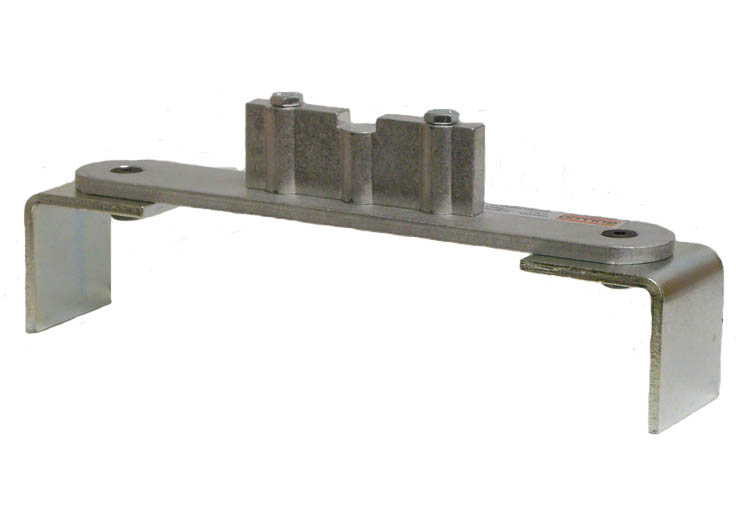

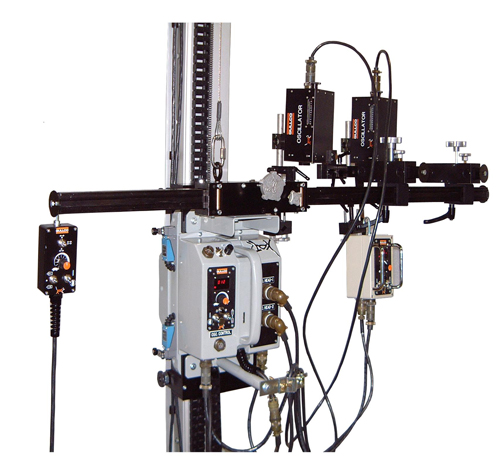

- Torch Support with rack arm and micro-slide rack box providing vertical torch adjustment, 4 axis torch holder assembly

- Tailstock...accurately adjustable with 6" (152mm) pneumatic clamping slide

- Bed heavy duty steel construction available in lengths up to 20 ft 6096mm)

The Gullco Automatic Rotary Weld System is also available as a multi-torch system.

Automatic Rotary Weld System

Automate your circumferential welding operations and add efficiency and increased precision with the highly flexible Gullco Automatic Rotary Weld System.

- rotary weld table with tack feedback interfaced with a PLC…providing precision stop/start, weld stop/start, adjustable rotation speed, weld overlap, multipass welding and tack welding

- accurately adjustable tailstock with 6″ (152mm) pneumatic clamping slide

- motorized torch positioning slide…enabling quick and easy loading/unloading of the workpiece

- maximum weight capacity 300 lbs (136kgs)

- table lengths up to 20 ft (6096mm)

Ideal for automating production of flanges, cylinders, end caps, valve components and other cylindrical parts.

The Gullco Automatic Rotary Weld System is a low cost automated welding machine that produces consistent, precision welds on cylindrical workpieces. It is designed to provide reliable quality welds, either in high or low production. It is easy to operate while providing sophisticated operational flexibility.

The Gullco Automatic Rotary Weld System comes complete with…

– Gullco programmable Motor Control interfaced with a PLC providing adjustable rotation speed, rotation stop/start, weld stop/start, wire feed stop/start and emergency stop controls, LED display for all functions

– Headstock…full 360° rotation with adjustable overlap, precision controlled electronically

– Multipass Welding…available with automatic torch height adjustment

– Torch Support with rack arm and micro-slide rack box providing vertical torch adjustment, 4 axis torch holder assembly

– Tailstock…accurately adjustable with 6″ (152mm) pneumatic clamping slide

– Bed heavy duty steel construction available in lengths up to 20 ft 6096mm)

The Gullco Automatic Rotary Weld System is also available as a multi-torch system.

Specifications

Specifications - Voltage

for operation on either 115/230 volt, single phase, 50/60 Hz AC power supply

Specifications - Drive Motor

24 volt DC

Specifications - Load Weight

300 lb

136 kg

Specifications - Pneumatic Tailstock Stroke

6 in

152 mm

Specifications - Max. Part Length

to 20 ft

to 6096 mm

Specifications - Weld Diameters

to 18 in

to 475 mm

Specifications - Adjustable Rotation Speed

0.25-15 rpm

Downloads

Related Products

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

Weld Positioner - Programmable - 0.75 - 12.5 RPM

Welding Electrode Stabilizing Ovens - In-Shop Models

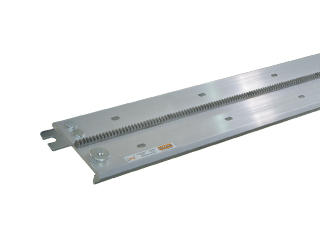

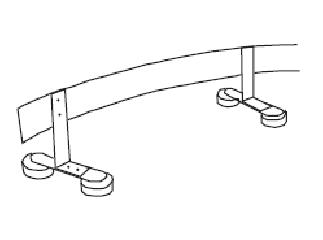

Side Beam

Product

MOGGY® - Magnetic Base - Stitch and Continuous Welding Carriage

MOGGY® - Stitch and Continuous Welding Carriage

MOGGY® - Dual Torch - Stitch Welding or Continuous Welding

Battery Powered Welding Automation - MOGGY® Carriage

Product

Pipe KAT® - Flexible Track - 115 VAC

Pipe KAT® - Flexible Track - 230 VAC

Product

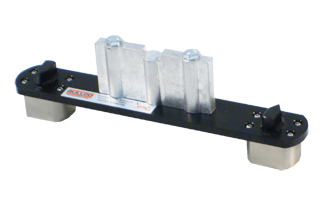

Self Aligning On/Off Magnet Assemblies

Product

Product

Product

Product

Product

Product

Product

Product

Product

Product

Product

Height Sensor has an adjustable swivel copper guide wheel to contact the work surface

Height Sensor has a stainless steel ball transfer that is particularly useful to maintain contact on curved surfaces or vertical applications

Seam Tracker is specifically designed for fillet welding applications

KAT® Weld Indexing Carriage - Flexible Track - 0.8 - 25.8 IPM (2 - 65.4 cm/min) - 115 VAC

KAT® Weld Indexing Carriage - Flexible Track - 0.8 - 25.8 IPM (2 - 65.4 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Flexible Track - 1.5 - 51.5 IPM (3.9 - 131 cm/min) - 42 VAC

KAT® Weld Indexing Carriage - Flexible Track - 1.5 - 51.5 IPM (3.9 - 131 cm/min) - 115 VAC

KAT® Weld Indexing Carriage - Flexible Track - 1.5 - 51.5 IPM (3.9 - 131 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Flexible Track - 4.2 - 139.1 IPM (10.6 - 353 cm/min) - 42 VAC

KAT® Weld Indexing Carriage - Flexible Track - 4.2 - 139.1 IPM (10.6 - 353 cm/min) - 115 VAC

KAT® Weld Indexing Carriage - Flexible Track - 4.2 - 139.1 IPM (10.6 - 353 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Rigid Track - 1 - 32.7 IPM (2.5 - 83.1 cm/min) - 115 VAC

KAT® Weld Indexing Carriage - Rigid Track - 1 - 32.7 IPM (2.5 - 83.1 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Rigid Track - 2.7 - 88.4 IPM (6.7 - 224 cm/min) - 42 VAC

KAT® Weld Indexing Carriage - Rigid Track - 2.7 - 88.4 IPM (6.7 - 224 cm/min) - 115 VAC

KAT® Weld Indexing Carriage - Rigid Track - 2.7 - 88.4 IPM (6.7 - 224 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Flexible Track - 0.8 - 25.8 IPM (2 - 65.4 cm/min) - 42 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 4.2 - 139.1 IPM (10.6 - 353 cm/min) - 42 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 4.2 - 139.1 IPM (10.6 - 353 cm/min) - 115 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 4.2 - 139.1 IPM (10.6 - 353 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 42 VAC

KAT® Weld Indexing Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 115 VAC

KAT® Weld Indexing Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 230 VAC

KAT® Weld Indexing Carriage - Rigid Track - 1 - 32.7 IPM (2.5 - 83.1 cm/min) - 42 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 0.8 - 25.8 IPM (2 - 65.4 cm/min) - 115 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 0.8 - 25.8 IPM (2 - 65.4 cm/min) - 230 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 1.5 - 51.5 IPM (3.9 - 131 cm/min) - 42 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 1.5 - 51.5 IPM (3.9 - 131 cm/min) - 115 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 1.5 - 51.5 IPM (3.9 - 131 cm/min) - 230 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 1 - 32.7 IPM (2.5 - 83.1 cm/min) - 115 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 1 - 32.7 IPM (2.5 - 83.1 cm/min) - 230 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 2.7 - 88.4 IPM (6.7 - 224 cm/min) - 42 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 2.7 - 88.4 IPM (6.7 - 224 cm/min) - 115 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 2.7 - 88.4 IPM (6.7 - 224 cm/min) - 230 VAC

KAT® Auto-weld Automation Carriage - Flexible Track - 0.8 - 25.8 IPM (2 - 65.4 cm/min) - 42 VAC

KAT®300 Welding Carriage | Radial Weld Oscillation

Kat Automatic Gouging Machine

KAT® Auto-weld Automation Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 42 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 115 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 0.5 - 16.4 IPM (1.2 - 41.6 cm/min) - 230 VAC

KAT® Auto-weld Automation Carriage - Rigid Track - 1 - 32.7 IPM (2.5 - 83.1 cm/min) - 42 VAC

KAT® Automation Carriage - Rigid Track - 0.5 - 16.4 IMP (1.2 - 41.6 cm/min) - 230 VAC

KAT® Automation Carriage - Rigid Track - 1 - 32.7 IMP (2.5 - 83.1 cm/min) - 42 VAC

KAT® Automation Carriage - Rigid Track - 1 - 32.7 IMP (2.5 - 83.1 cm/min) - 230 VAC

KAT® Automation Carriage - Rigid Track - 2.7 - 88.4 IMP (6.7 - 224 cm/min) - 42 VAC

KAT® Automation Carriage - Rigid Track - 2.7 - 88.4 IMP (6.7 - 224 cm/min) - 115 VAC

KAT®300 Welding Carriage | Linear Weld Oscillation

KAT® Automation Carriage - Flexible Track - 4.2 - 139.1 IMP (10.6 - 353 cm/min) - 115 VAC

KAT® Automation Carriage - Flexible Track - 4.2 - 139.1 IMP (10.6 - 353 cm/min) - 230 VAC

KAT® Automation Carriage - Rigid Track - 0.5 - 16.4 IMP (1.2 - 41.6 cm/min) - 42 VAC

KAT® Automation Carriage - Rigid Track - 1 - 32.7 IMP (2.5 - 83.1 cm/min) - 115 VAC

KAT® Automation Carriage - Rigid Track - 2.7 - 88.4 IMP (6.7 - 224 cm/min) - 230 VAC

KAT® Automation Carriage - Rigid Track - 0.5 - 16.4 IMP (1.2 - 41.6 cm/min) - 115 VAC

KAT® Automation Carriage - Flexible Track - 0.8 - 25.8 IMP (2 - 65.4 cm/min) - 230 VAC

KAT® Automation Carriage - Flexible Track - 1.5 - 51.5 IMP (3.9 - 131 cm/min) - 42 VAC

KAT® Automation Carriage - Flexible Track - 1.5 - 51.5 IMP (3.9 - 131 cm/min) - 115 VAC

KAT® Automation Carriage - Flexible Track - 1.5 - 51.5 IMP (3.9 - 131 cm/min) - 230 VAC

KAT® Automation Carriage - Flexible Track - 4.2 - 139.1 IMP (10.6 - 353 cm/min) - 42 VAC

KAT® Automation Carriage - Flexible Track - 0.8 - 25.8 IMP (2 - 65.4 cm/min) - 42 VAC

KAT® Automation Carriage - Flexible Track - 0.8 - 25.8 IMP (2 - 65.4 cm/min) - 115 VAC

Automatic Pipe Turning Rolls for Welding - KAMEL Rolls

Automatic Pipe Turning Rolls for Welding - KAMEL Rolls

Automatic Pipe Turning Rolls for Welding - KAMEL Rolls

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Electrode Stabilizing Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A