MOGGY® – Stitch and Continuous Welding Carriage

MOGGY® - Stitch and Continuous Welding Carriage

Item # GM-03-100 — MOGGY® – Stitch and Continuous Welding Carriage

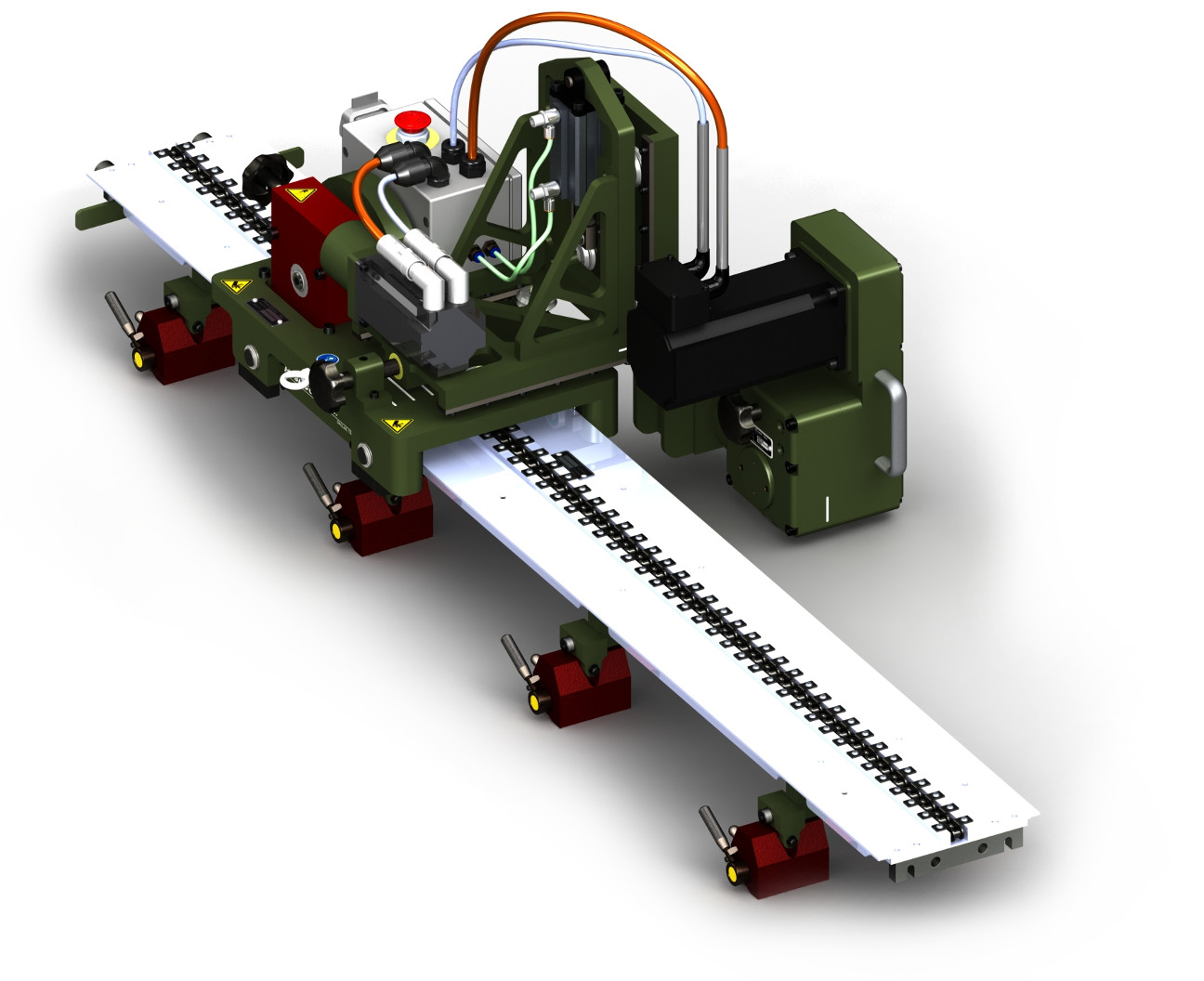

- Ideal for automatic horizontal fillet, lap and butt welding operations

- Controls are available to perform continuous and/or stitch weld operations

- Dual gun holder assembly is available for efficient simultaneous welding

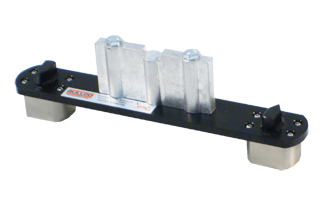

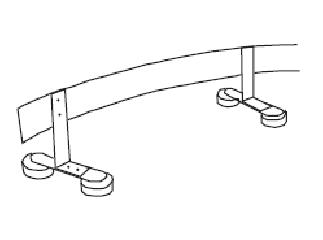

- Wheels on the standard Moggy can be reversed to allow the moggy to run on standard v-groove track

- The magnetic moggy has a magnetic base that clings to the vertical member for out of position applications

MOGGY® Automated Welding System

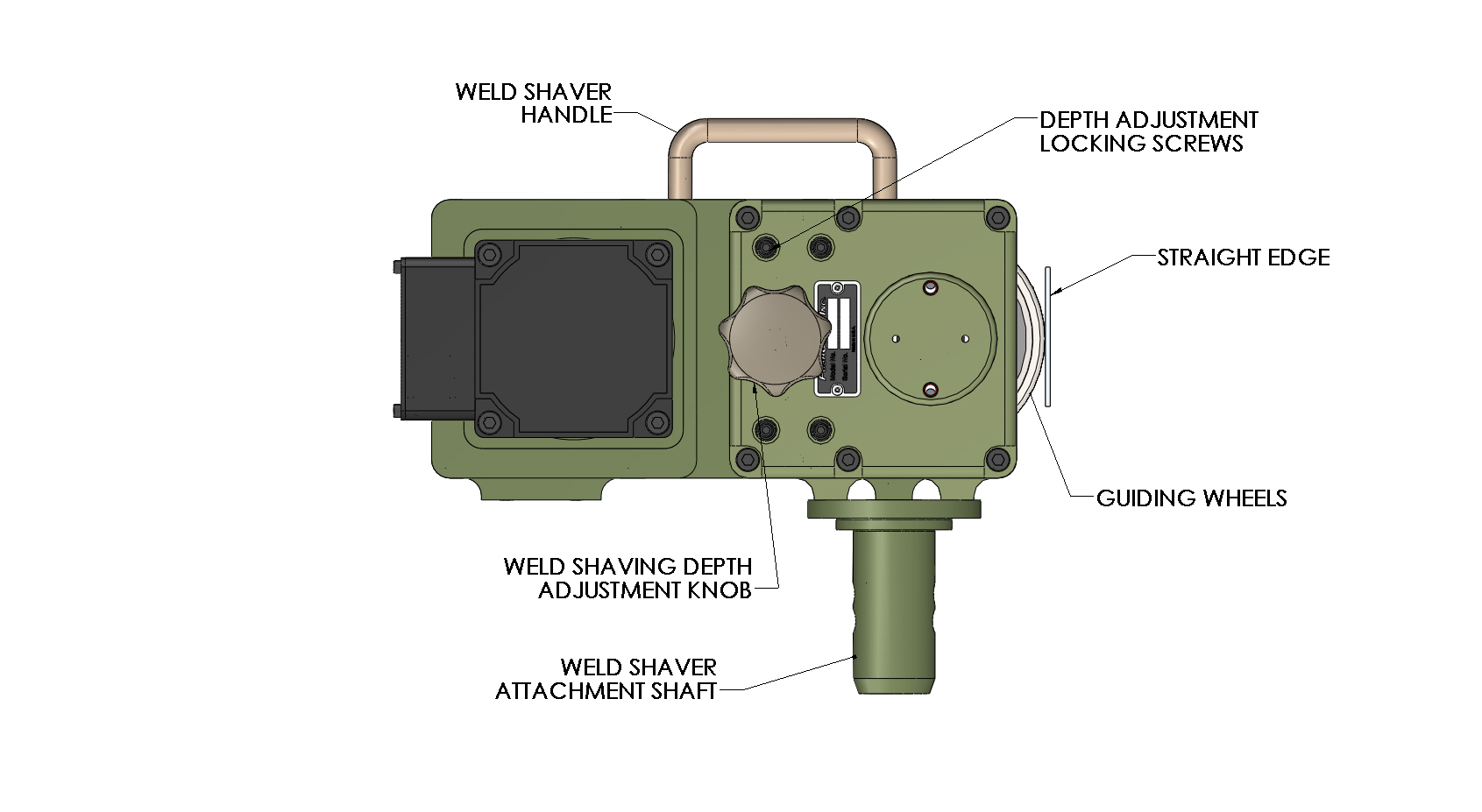

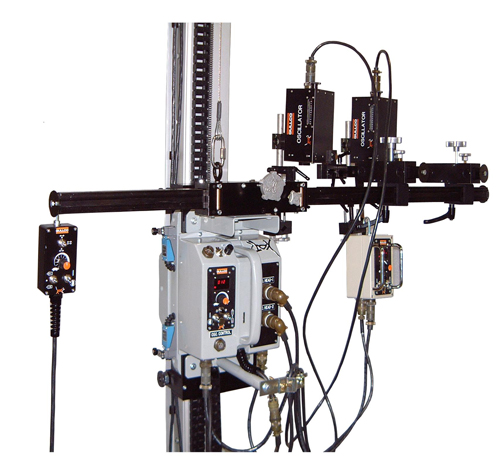

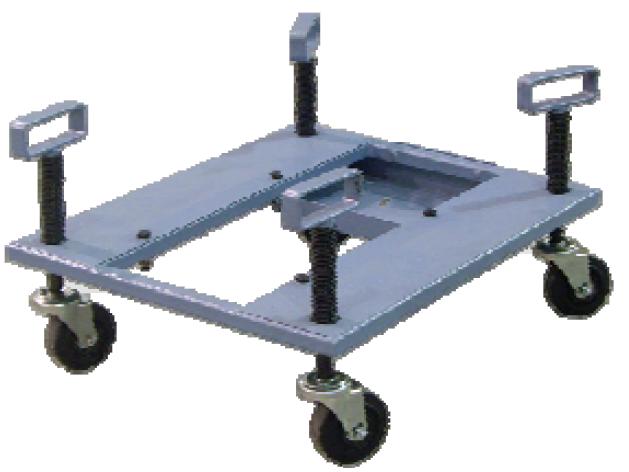

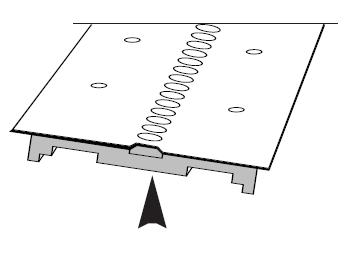

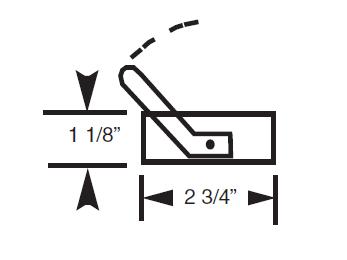

The MOGGY® is intended to automate and improve the quality of welding and cutting operations by carrying the welding gun(s) or cutting torch(es), at precisely controlled speeds, along the path of the joint. The MOGGY® carriage also provided interface betweenthe welding and cutting motion and the arc start and stop signals. The automation carriage is normally guided by adjustable guide wheels which are set to always drive the carriage slightly into the vertical member (usually either the vertical member of a filler joint or a template/fence placed parallel to the joint). Industry standard 6" v-groove track may also be used to guide the path of the MOGGY®. The carriage is flexible enough to allow it to be easily configured for horizontal lap, butt and fillet weld joints as well as a variety of cutting processes.

Using the MOGGY® automation carriage system will add accuracy and uniformity to welding and cutting applications while increasing productivity. Typical applications include shipbuilding, offshore construction, bridge and railcar construction along with a variety of other steel fabrication applications.

MOGGY® - GM-03-100

Trackless welding automation carriage for stitch or continuous welding. Come with a control that uses a Gullco microprocessor to provide accurate repeatability regardless of travel speeds or weld distance. It has a foward/stop/reverse switch, wire feed start on/off switch, travel speed potentiometer, auto wire feed start with delay carriage start, wire feed connector with 15ft. (4572mm) control cable. All functions displayed in an highly visible LED window.

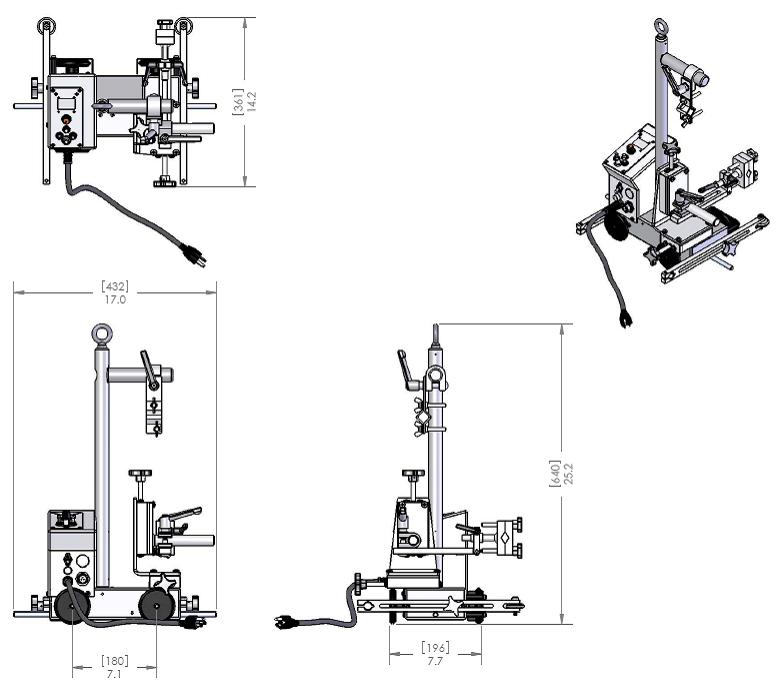

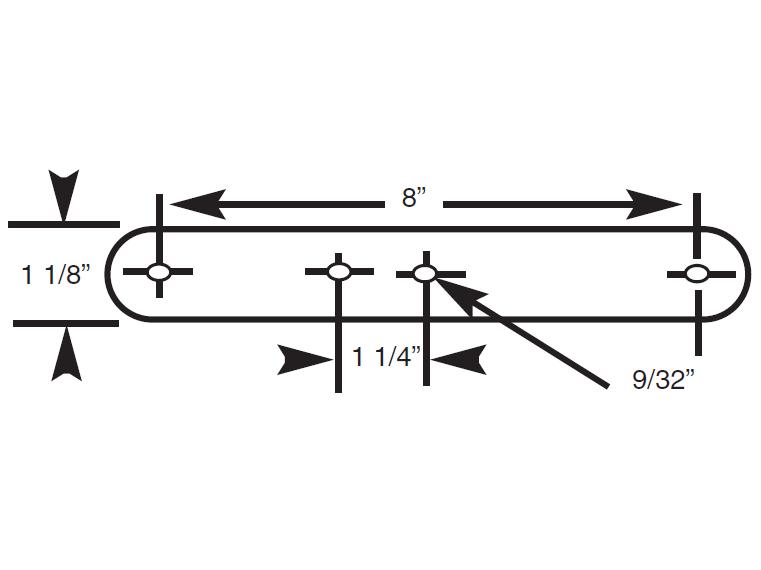

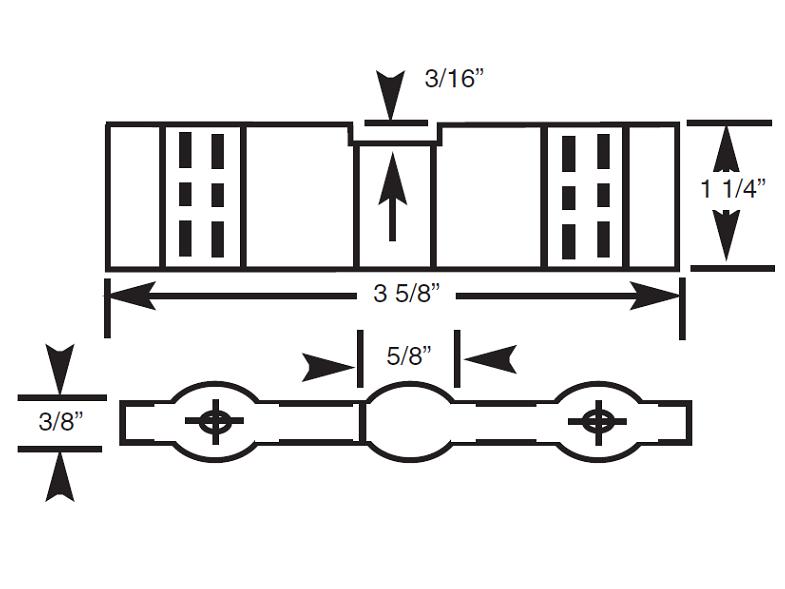

Specifications

Specifications - Type

Standard

Specifications - Speed Range

3.25 to 100.50 in/min

8.26 to 255.27 cm/min

Specifications - Length

17 in

431.8 mm

Specifications - Width

14 in

355.7 mm

Specifications - Height

25 in

635 mm

Specifications - Weight

31 lb

14.1 kg

Downloads

Related Products

KAT® 100 Mechanized Welding and Cutting Carriage

Through Hole Weld Positioner - Programmable - 0.75 - 12.5 RPM

Weld Positioner - Programmable and Gas Purge - 0.75 - 12.5 RPM

Weld Positioner - Programmable - 0.27 - 4.63 RPM

Through Hole Weld Positioner - Programmable - 0.27 - 4.63 RPM

Weld Positioner - Programmable and Gas Purge - 0.27 - 4.63

Center Bonded Mounts STA Series

All Product Categories

Weld Automation

Portable Beveling Machines

Ceramic Weld Backing

Welding Rod Ovens

Accessories

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A